6

Maintenance and Adjustment

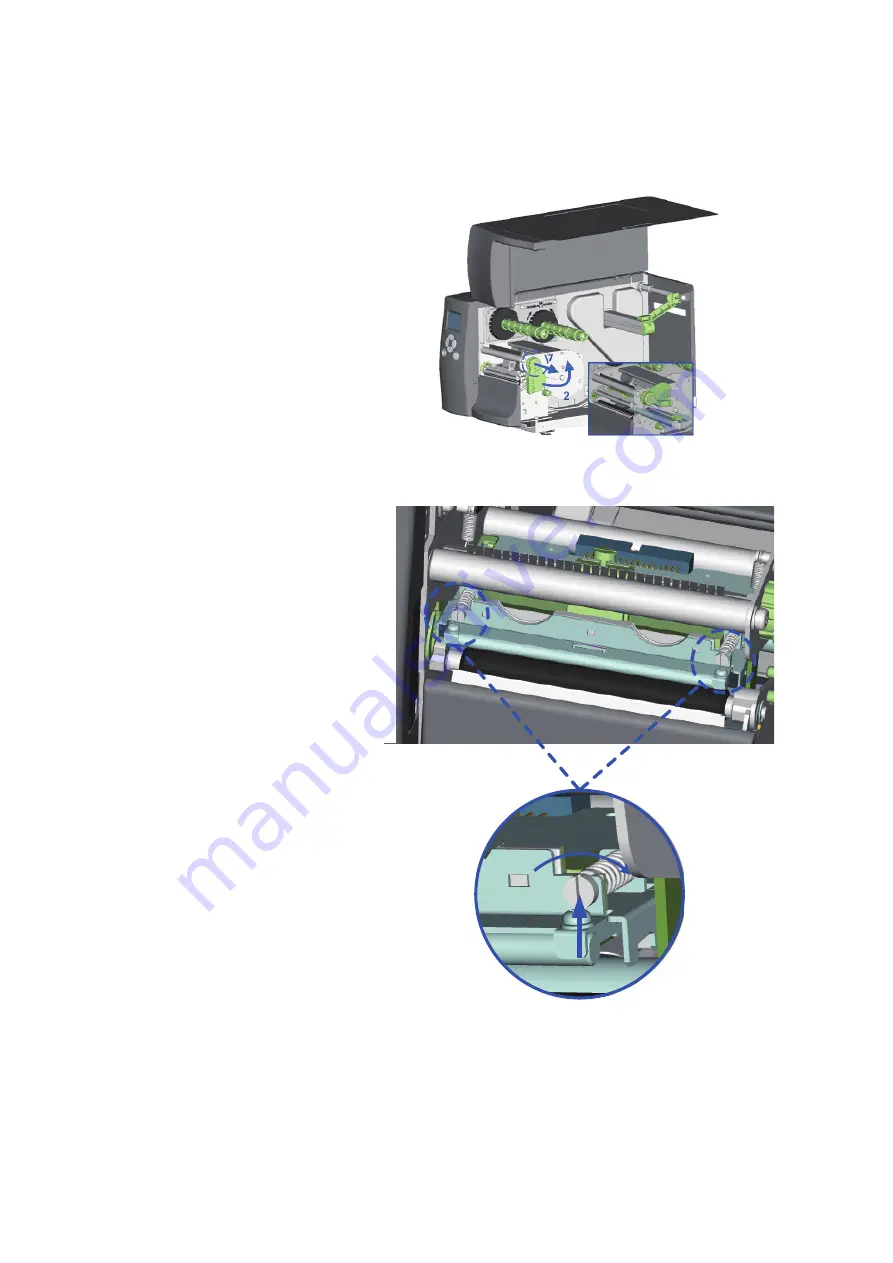

6.2 Adjusting the print line

A

48

1. Open the Printer’s top cover.

2. Pull the Printhead Lever out

and rotate it upward to the

right (counterclockwise) to

open the Printhead.

3. Move the Print Line all the way back

by turning the screws on each side of

the Printhead (marked A)

counterclockwise.

4. Then turn the screws clockwise a

quarter turn at a time to move the

Print Line forward. Adjust both screws

by the same amount to ensure that

the Print Line and the Platen Roller

are parallel.

5. Print a test label with a black bar

across the entire width of the label

to check print quality and repeat

step 4 as necessary to achieve

proper print quality.

When printing on stiff or thick paper, the Print Line needs to be moved forward (paper feed direction)

in order to achieve better print quality.