Operation Manual – TEXI 781 SERVO

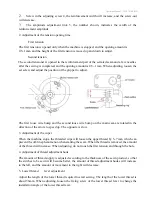

Same as the adjustment method of the head start fork. When the low speed is running, loosen the

fixing screw of the speed reduction mechanism fork and adjust the position of the speed reduction

mechanism fork. However, adjust the limit screw at high speed.

The standard movement of the fork is 14mm. Adjust the pad with the shift fork to adjust. When

you spin it out, the stroke is reduced.

Note: If the fork is swung too far at low speed and parking, the fork cam is not properly installed.

Therefore, the fork cam should be installed parallel to the processing surface of the fork cam

holder.

The phenomenon when the adjustment value changes:

When the speed adjustment mechanism fork adjustment is not possible, please adjust the fork

adjustment pad.

The adjustment of other parts

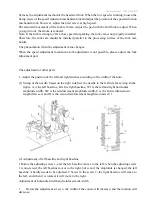

1. Adjust the position of the left and right stitches according to the width of the hole:

(1)

Swing of the needle: based on the right side,Sew the needle to the left side for sewing.In the

figure, A is the left baseline, B is the right baseline, W1 is the left and right horizontal

amplitude width, W2 is the reinforcement amplitude width, C is the first reinforcement

length (first set), and D is the second reinforcement length (second set) ).

(2)

Adjustment of left baseline and right baseline

1 Rotate the adjusting screw 1, and the left baseline moves to the left; when the adjusting screw

1 is unscrewed, the left baseline moves to the right, but even if the amplitude is changed, the left

baseline A hardly needs to be adjusted. 2 Screw in the screw 2, the right baseline will move to

the left, and when it is rotated, it will move to the right.

Adjustment of horizontal width and reinforcement width

1

Rotate the adjustment screw 3, the width of the course will increase, and the rotation will

decrease.