D

V

ESR

+

I

OUT

R

ESR

C

min

+

I

OUT

ǒ

V

OUT

*

V

BAT

Ǔ

ƒ

D

V

V

OUT

L

+

V

BAT

ǒ

V

OUT

–V

BAT

Ǔ

D

I

L

ƒ

V

OUT

TPS61090, TPS61091, TPS61092

www.ti.com

SLVS484C – JUNE 2003 – REVISED DECEMBER 2014

The second parameter for choosing the inductor is the desired current ripple in the inductor. Normally, it is

advisable to work with a ripple of less than 20% of the average inductor current. A smaller ripple reduces the

magnetic hysteresis losses in the inductor, as well as output voltage ripple and EMI. But in the same way,

regulation time at load changes rises. In addition, a larger inductor increases the total system costs. With those

parameters, it is possible to calculate the value for the inductor by using

Equation 5

:

(5)

Parameter f is the switching frequency and

Δ

I

L

is the ripple current in the inductor, i.e., 20% × I

L

. In this example,

the desired inductor has the value of 5.5 µH. With this calculated value and the calculated currents, it is possible

to choose a suitable inductor. Care has to be taken that load transients and losses in the circuit can lead to

higher currents as estimated in equation 4. Also, the losses in the inductor caused by magnetic hysteresis losses

and copper losses are a major parameter for total circuit efficiency.

The following inductor series from different suppliers have been used with the TPS6109x converters:

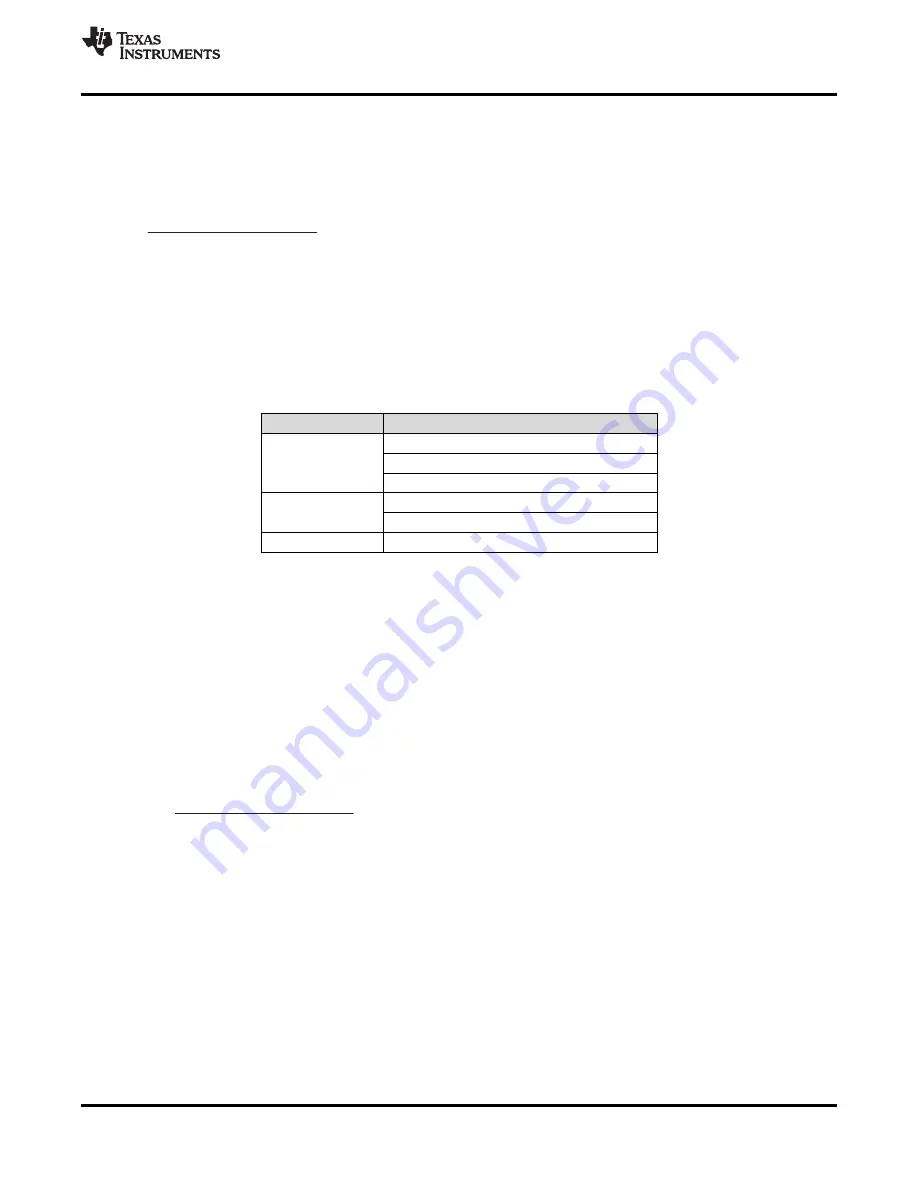

Table 4. List of Inductors

VENDOR

INDUCTOR SERIES

CDRH6D28

Sumida

CDRH6D38

CDRH103R

Wurth Elektronik

WE-PD type L

WE-PD type XL

EPCOS

B82464G

10.2.1.2.4

Capacitor Selection

10.2.1.2.4.1

Input Capacitor

At least a 10-µF input capacitor is recommended to improve transient behavior of the regulator and EMI behavior

of the total power supply circuit. A ceramic capacitor or a tantalum capacitor with a 100-nF ceramic capacitor in

parallel, placed close to the IC, is recommended.

10.2.1.2.4.2

Output Capacitor DC-DC Converter

The major parameter necessary to define the minimum value of the output capacitor is the maximum allowed

output voltage ripple in steady state operation of the converter. This ripple is determined by two parameters of

the capacitor, the capacitance and the ESR. It is possible to calculate the minimum capacitance needed for the

defined ripple, supposing that the ESR is zero, by using equation

Equation 6

:

(6)

Parameter

f

is the switching frequency and

Δ

V is the maximum allowed ripple.

With a chosen ripple voltage of 10 mV, a minimum capacitance of 53 µF is needed. The total ripple is larger due

to the ESR of the output capacitor. This additional component of the ripple can be calculated using

Equation 7

:

(7)

An additional ripple of 40 mV is the result of using a tantalum capacitor with a low ESR of 80 m

Ω

. The total ripple

is the sum of the ripple caused by the capacitance and the ripple caused by the ESR of the capacitor. In this

example, the total ripple is 50 mV. Additional ripple is caused by load transients. This means that the output

capacitance needs to be larger than calculated above to meet the total ripple requirements. The output capacitor

has to completely supply the load during the charging phase of the inductor. A reasonable value of the output

capacitance depends on the speed of the load transients and the load current during the load change. With the

calculated minimum value of 53 µF and load transient considerations, a reasonable output capacitance value is

in a 100 µF range. For economical reasons this usually is a tantalum capacitor. Because of this the control loop

has been optimized for using output capacitors with an ESR of above 30 m

Ω

.

Copyright © 2003–2014, Texas Instruments Incorporated

Submit Documentation Feedback

15

Product Folder Links:

TPS61090 TPS61091 TPS61092