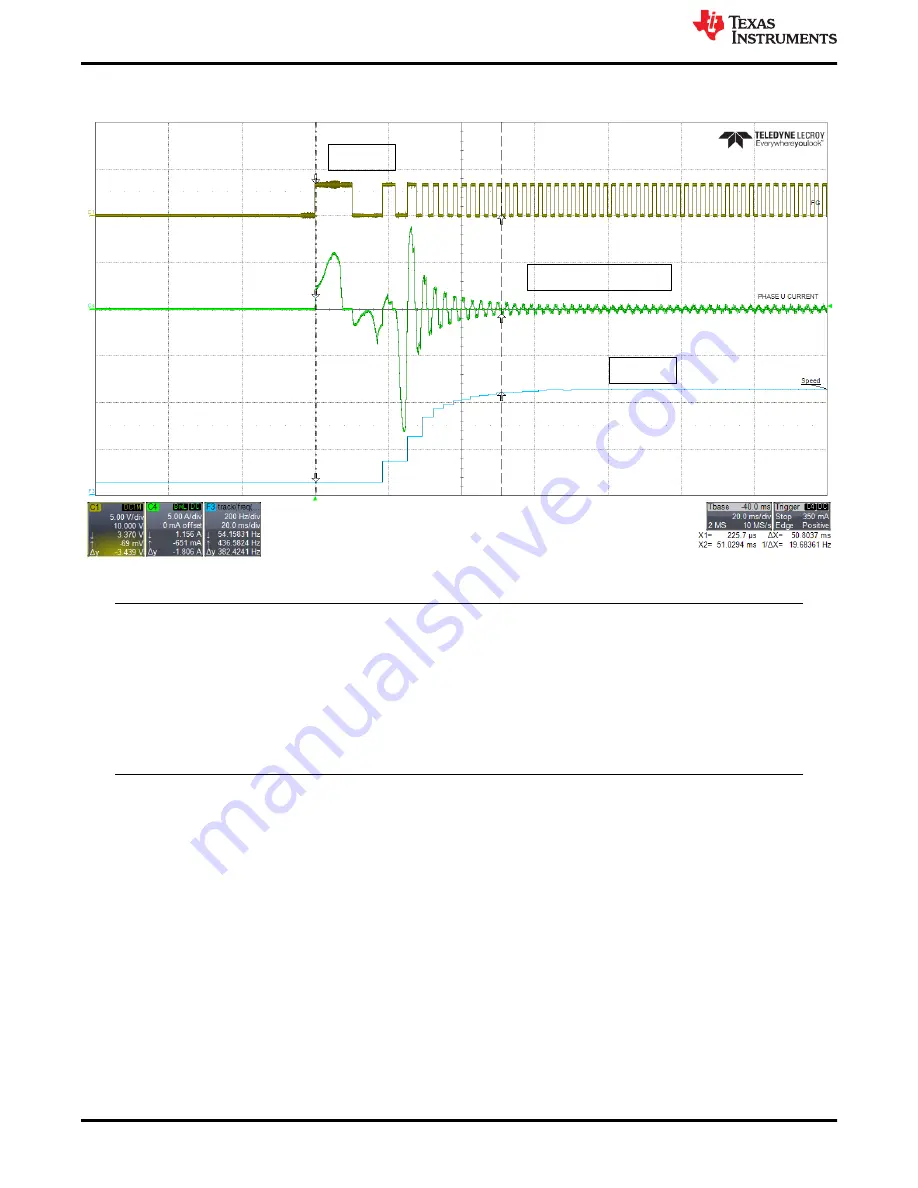

shows FG, phase current and motor electrical speed waveform. Motor takes 50 ms to reach target

speed from zero speed.

Phase current

Speed

FG

Figure 4-2. Phase current, FG and motor speed - Faster startup time

Note

If Abnormal speed fault [ABN_SPEED] or Loss of sync [LOSS_OF_SYNC] fault gets triggered, it is

recommended to follow below debug steps.

1. Select Double align as the motor startup method in [MTR_STARTUP].

2. Increase align time [ALIGN_TIME].

3. Configure align current threshold [ALIGN_CURR_THR] to 50% of cycle by cycle current limit

[ILIMIT].

4. Configure First cycle frequency select [FIRST_CYCLE_FREQ_SEL] to 0.

4.3.5 Improving speed regulation

For applications that require better speed regulation, it is recommended to tune Speed loop PI controllers

[SPD_LOOP_KP] and [SPD_LOOP_KI]. Kp coefficient of speed loop [SPD_LOOP_KP] controls the settling time

and speed overshoots. Ki coefficient of Speed loop [SPD_LOOP_KI] controls speed overshoot and ensures

regulation of speed at set value and drives the error to zero.

Step 1: Enable speed loop [SPEED_LOOP_DIS]

Step 2: Tuning speed loop Kp [SPD_LOOP_KP] and Ki [SPD_LOOP_KI] is experimental. It is recommended to

manually tune Speed loop Kp and Ki till the desired results are achieved.

Refer to

to read back motor speed using DACOUTs.

4.3.6 Stopping motor quickly

MCT8316A provides two options for applications that require stopping the motor quickly.

Option 1: Stopping motor quickly while spinning in closed loop.

Basic Controls

18

MCT8316A Tuning Guide

SLLU336 – MAY 2021

Copyright © 2021 Texas Instruments Incorporated