Load Current (A)

Outp

u

t

Vo

lta

g

e

(V)

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

11.88

11.9

11.92

11.94

11.96

11.98

12

12.02

12.04

12.06

12.08

12.1

12.12

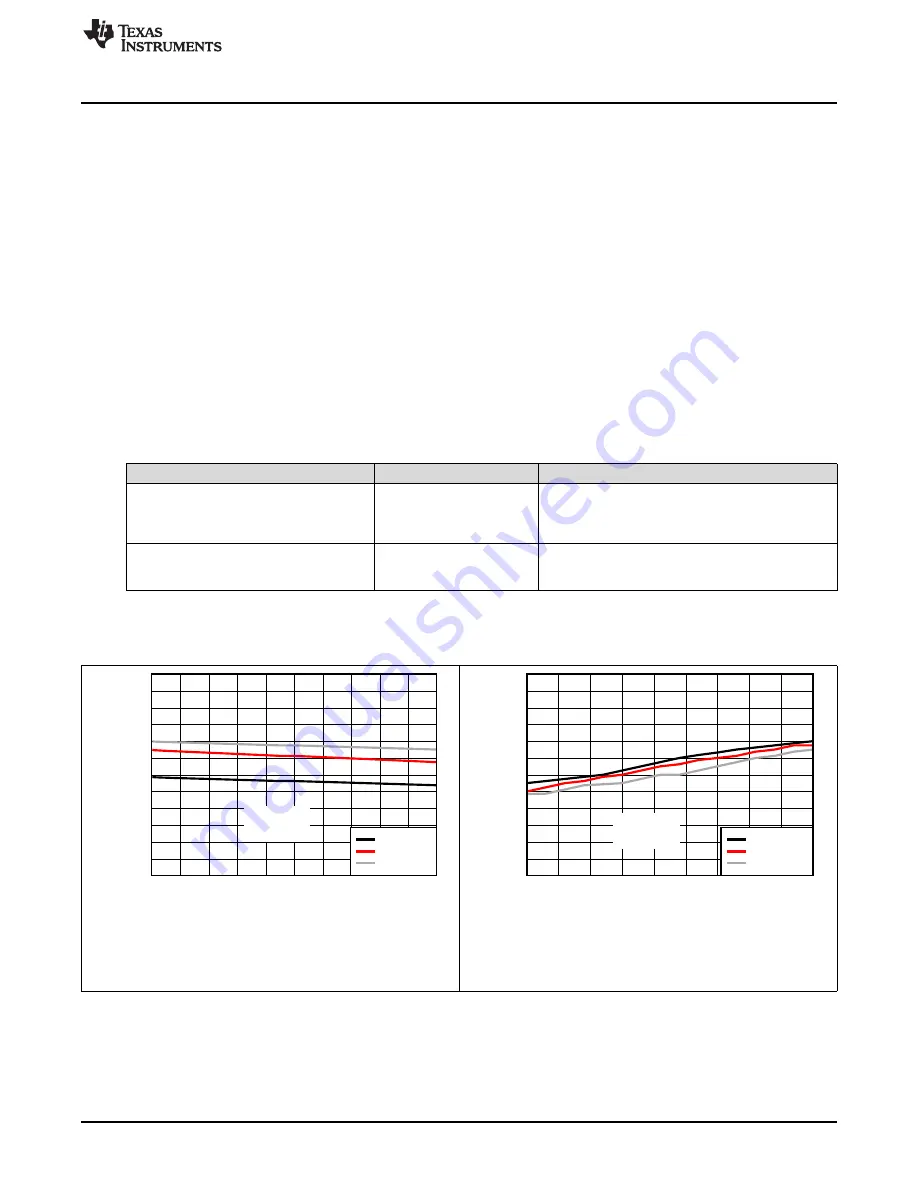

Ext-V

CC

FPWM = 1

VIN = 24 V

VIN = 48 V

VIN = 60 V

Input Voltage (V)

Ou

tp

u

t

V

o

lta

g

e

(V

)

15

20

25

30

35

40

45

50

55

60

11.88

11.9

11.92

11.94

11.96

11.98

12

12.02

12.04

12.06

12.08

12.1

12.12

Ext-V

CC

FPWM = 1

I

OUT

= 0 A

I

OUT

= 0.5 A

I

OUT

= 1 A

Typical Performance Curves

7

SNVU504A – August 2016 – Revised August 2016

Copyright © 2016, Texas Instruments Incorporated

LM5161 Buck EVM User’s Guide

When selecting the FPWM mode, the LM5161 needs an external feedback ripple injection circuit (Type 3)

or

the external ESR resistor (Type 1) on board, for normal operation. The correct values for the external

ESR resistor (R4 in the EVM) in series with the output capacitors (C10, C11) or for the external ripple

injection circuit (R6,C7 and C10), depending on which ripple injection scheme (Type 1 or Type 3) is used,

are calculated based on the formulae mentioned in the

datasheet. See application note

for more details for each ripple generation method.

When selecting the DCM mode setting using the Jumper (

JP1

) see

, the internal emulated ripple

mode is enabled. When operating in this mode, there is no need to add the external ESR resistor in series

with the output capacitors or the external ripple injection circuit (see

for more details). The

internal emulated ripple is sufficient to maintain steady-state and dynamic stability while operating in this

mode. In a typical buck application at T

J

> 125°C and FPWM = 0, with the input voltage VIN > 72 V and

the V

CC

externally supplied add a BST resistor, R2 (recommended > 3

Ω

) in series with the BST capacitor

(see

). This protects the internal bootstrap diode during a full load transient operation.

An external voltage can be supplied to the VCC pin in the range of 9 V to 13 V, for improved efficiency

requirements. In that case, the diode D1 must be appropriately populated. The user can keep diode D1

populated on board and install/uninstall the jumper

J4

in order to estimate the difference in efficiency, with

and without the external V

CC

supply. More details about the diode D1 are given in the

Table 2. FPWM Pin Mode

JP1 Setting

Logic Stage

Description

DCM or Floating (High Z) (Pin 2 - Pin 3:

DCM)

0

The FPWM pin is grounded or left floating. Populate

resistor R2 appropriately. DCM with the pulse

skipping mode at light load enabled. No external

ripple injection circuit needed.

FPWM (VCC) (Pin 2 - Pin 1: FPWM)

1

The FPWM pin is connected to VCC. External Ripple

Injection circuit needed. CCM mode enabled over the

entire load range.

4

Typical Performance Curves

V

OUT

- V

CC

diode

connected

FPWM = 1

F

SW

= 300kHz

Figure 2. Load Regulation

V

OUT

- V

CC

diode

connected

FPWM = 1

F

SW

= 300kHz

Figure 3. Line Regulation