DCIN

PCB Layout Guideline

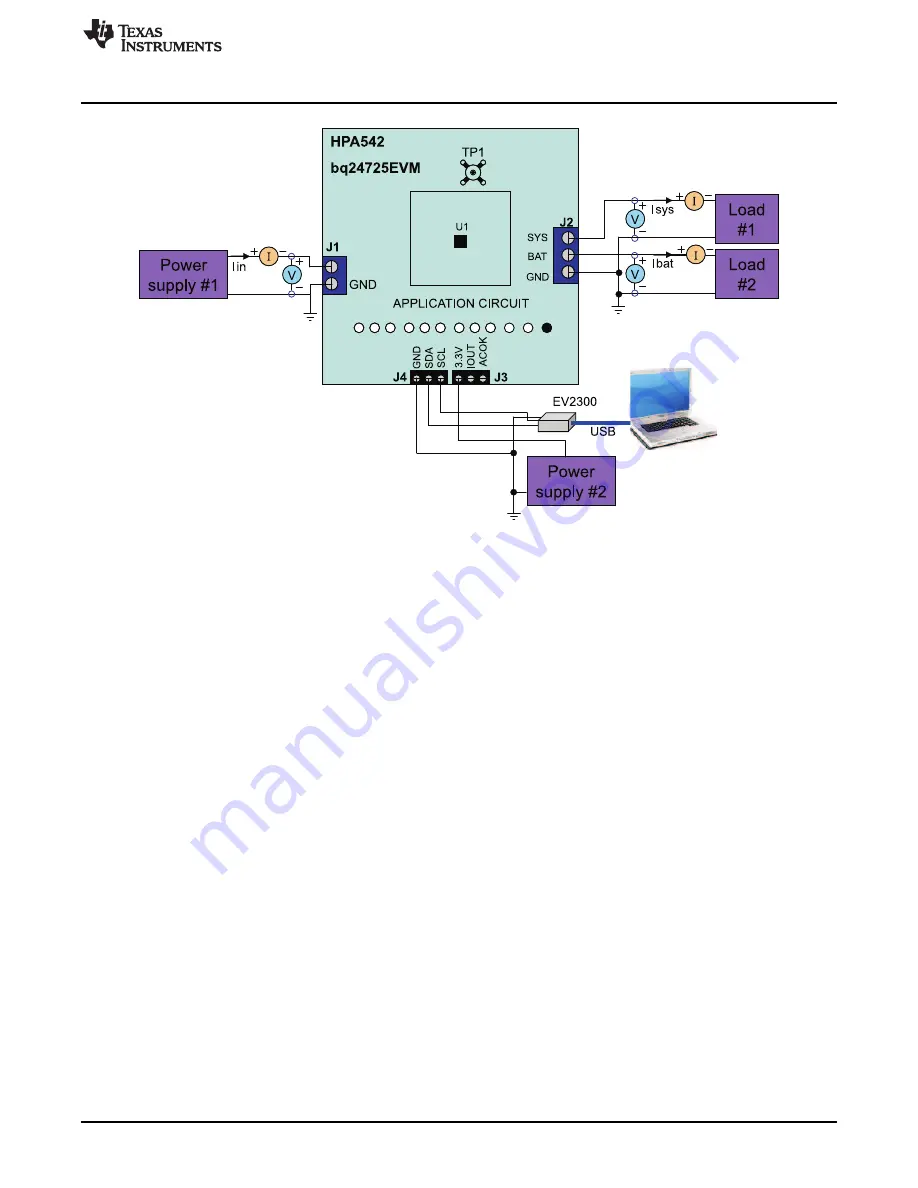

Figure 4. Test Setup for HPA-542

4. Type in "7905" in the Charge Option, and click the Write button. This enables charging.

Measure

→

Ibat = 500 mA

±

100 mA

5. Type in "2944" (mA) in the Charge Current DAC, and click the Write button. This sets the battery

charge current regulation threshold to 2.944 A.

Measure

→

Ibat = 3000 mA

±

300 mA

Measure

→

V(TP(IOUT)) = 340 mV

±

40 mV

6. Enable the output of the Load #1.

Measure

→

Isys = 3000 mA

±

300 mA, Ibat = 1600 mA

±

200 mA, Iin = 4100 mA

±

400 mA

Measure

→

V(TP(IOUT)) = 820 mV

±

100 mV

7. Turn off the Load #1.

Measure

→

Isys = 0 A

±

100 mA, Ibat = 3000 mA

±

300 mA.

8.

2.4.4

Power Path Selection

1. Type in "7905" in the Charge Option, and click the Write button. This disables charging.

2. Replace Load #2 and current meter with PS#3. Make sure a voltage meter is connected across J2

(BAT, GND). Enable the output of the PS #3. Ensure that the output voltage is 10 V

±

500 mV.

Measure

→

Measure

±

V(J2(SYS)) = 19.5 V

±

1 V (adapter connected to system)

3. Turn off PS#1.

Measure

→

V(J2(SYS)) = 10 V

±

1 V (battery connected to system)

Measure

→

V(J2(BAT)) = 10 V

±

1 V (battery connected to system)

3

PCB Layout Guideline

The switching node rise and fall times must be minimized for minimum switching loss. Proper layout of the

components to minimize high-frequency current path loop is important to prevent electrical and magnetic

field radiation and high-frequency resonant problems. The following is a printed-circuit board (PCB) layout

priority list for proper layout. Laying out a PCB according to this specific order is essential.

7

SLUU439A

–

August 2010

–

Revised May 2011

bq24725EVM Evaluation Module

Copyright

©

2010

–

2011, Texas Instruments Incorporated