TESTING

Bluhm & Feuerherdt GmbH

Production and Distribution of

Systems for the Testing of

Construction Materials

Motzener Str. 26b

DE - 12277 Berlin, Germany

Tel. +49 / 30 / 710 96 45-0

Fax +49 / 30 / 710 96 45-97

www.testing.de

1

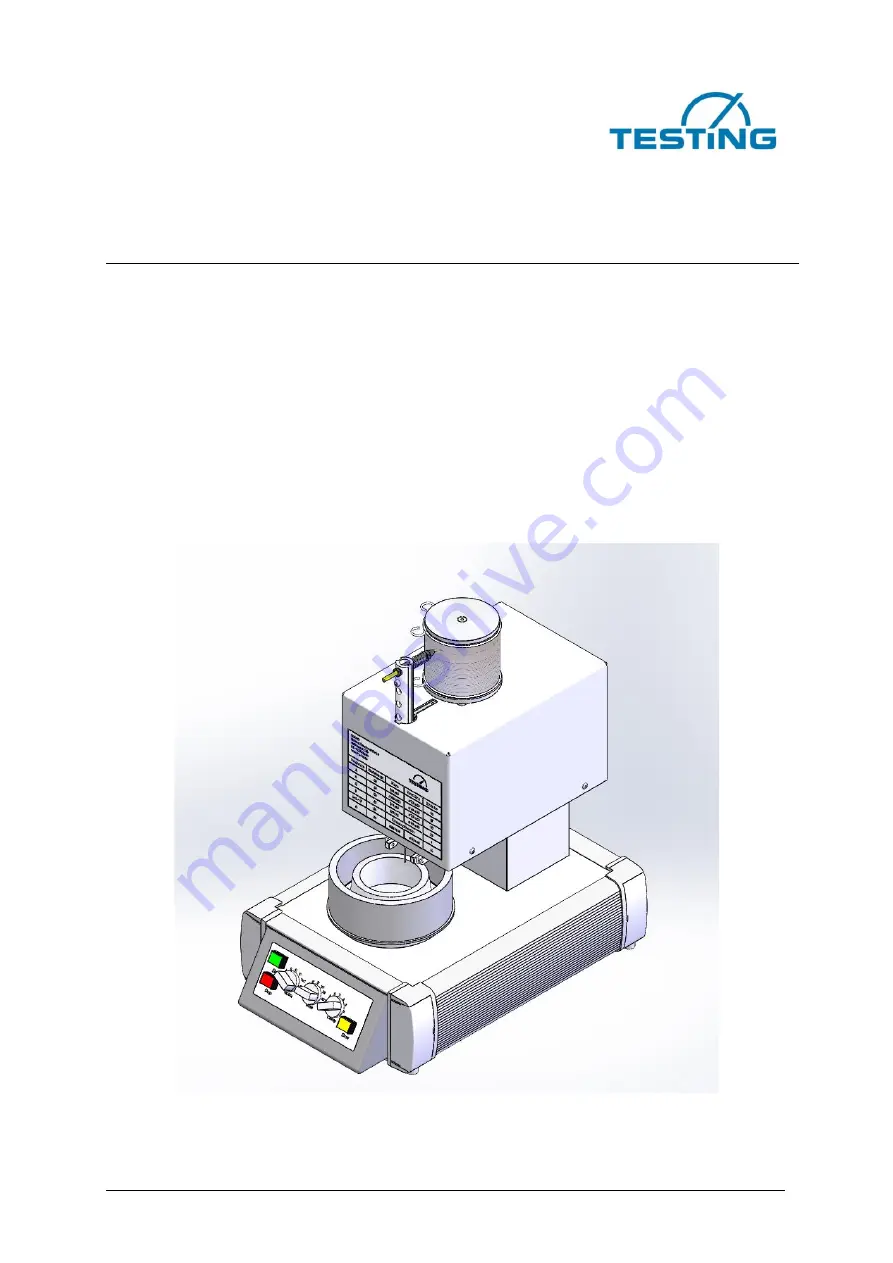

Operating Manual

Automatic Vicat Needle Apparatus