8

NOTE: In order to control the Gate/Vibratory Motor

the Spinner/Auger must be active, if it is not active the

Gate/Vibe label state will blink indicating the motor is

disabled.

Main Menu

Pressing the menu button will enter the main menu.

Once in the main menu, the user can select the following:

Operation

Default Motor Controls

Starting and

Stopping Spreader

Press the ON button to turn on

the spinner/auger.

Press the OFF button to turn off

the spinner/auger

Gate/Vibe Control

Press the OPEN/ON button to

open the gate or to turn on the

vibe.

Press the CLOSE/OFF button to

close the gate or to turn off the

vibe.

Adjusting Motor

Speed

Press the bottom left button

(down arrow) to decrease the

speed of the motor in 11%

increments.

Press the bottom mid button (up

arrow) to increase the speed of

the motor in 11% increments.

Entering the Menu

Press the bottom right button

(menu) to enter the menu.

Maintenance Menu

Reverse Auger

The reverse auger feature allows users to reverse the

auger in case of a jam.

To activate the reverse auger feature:

1. Select maintenance for the main menu.

2. Press start. The auger will pulse 3 times and the start

button changes to pulsing to indicate the auger is

turning.

3. If the auger needs to be reversed further, press start

again and wait for the reverse cycle to complete.

4. Press the exit button to return to the main menu.

5. If jam cannot be cleared, refer to cleaning auger

section

Menu Options

Diagnostics

Review the warning and fault list.

Maintenance

Displays maintenance menu with

options to reverse auger.

Settings

Adjusts the parameters of the display.

System

Display system’s voltage and

temperature.

Support

Displays support information.

Controller Info Displays controller information

Display Info

Displays system information.

Exit

Returns to the home page.

Summary of Contents for 45-0592

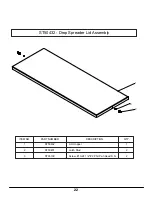

Page 12: ...12 2 3 4 6 10 5 11 8 7 11 10 1 9 45 0593 Drop Spreader 2 In Receiver...

Page 14: ...14 45 0592 Drop Spreader with 3 Pt Hitch Mount 3 7 8 4 5 10 2 1 6 11 12 9 13 14 15 17 16...

Page 17: ...17 This Page Intentionally Left Blank...

Page 23: ...23 This Page Intentionally Left Blank...

Page 24: ...24 SA10051 Controls and Wiring 1 2 3 7 6 8 4 5...

Page 26: ...26 This Page Intentionally Left Blank...