7. Troubleshooting

7.1 Troubleshooting

Even if the same failure occurs, the cause and action may be different. In addition, there may be

two or more causes.

If the cause and action cannot be determined using the following table, stop the operation

immediately and contact a specialist company or the service center specified by the

manufacturer.

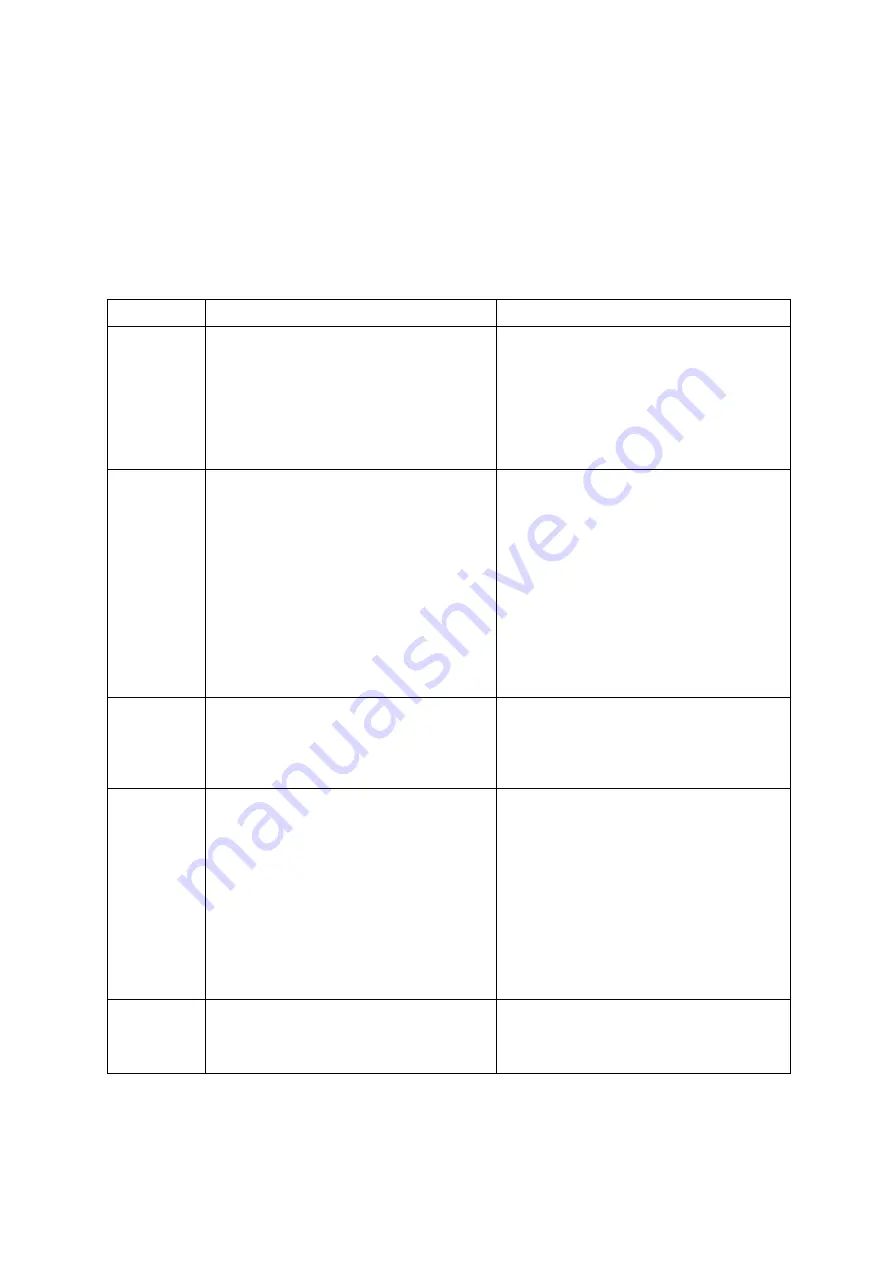

Failure Cause

Action

The bearing

temperature

is high.

Excess or lack of grease

Poor fit between the bearing inner ring

and the main shaft

Poor connection between the outer ring

and bearing case of the bearing

Deterioration of grease, or entry of

moisture

Excessive tension of the V-belt

Adjust it to the proper amount.

Replace the main shaft.

Replace the bearing.

Change the grease. Replace the bearing.

Readjust the V-belt tension.

Strong

vibration

Corrosion or wear in the impeller, or

foreign matter on the impeller

Poor connection between the impeller

boss and the main shaft

Unbalance of the V-belt pulley

Bend of the main shaft

Contact between the rotor and casing

Resonance caused by insecure

foundations

Insufficient tightening of the mounting bolt

Damage to the bearing

Remove the foreign matter adhered to the

impeller. Correct the balance of the

impeller.

Replace the impeller or the main shaft.

Replace the V-belt pulley, or correct the

balance of the pulley.

Replace the main shaft.

Reassemble the casing.

Reinforce the foundations.

Retighten the bolt and nut.

Replace the bearing.

Abnormal

noise

Damage to the bearing

Intake of foreign matter

Contact between the rotor and casing

Contact with the belt guard

Replace the bearing.

Inspect the inside of the casing.

Avoid the contact between the rotor,

casing, and air intake.

Readjust the V-belt tension,

Low

performance

Decrease in rotational speed or

frequency

Reverse rotation

Corrosion or wear in the impeller, or

foreign matter on the impeller

Clogging of the intake filter

Failure in opening/closing of the damper

Dust deposited inside the casing and duct

Excessive resistance

Errors in calculating the specific weight of

gas

Regulate the power supply.

Swap the wires of the motor.

Clean, repair, or replace the impeller.

Clean the intake filter.

Repair the damper.

Clean the place.

Consider installing a booster fan, or

replace the V-belt pulley.

Measure the specific weight, or perform a

gas analysis.

Motor

overload

Insufficient resistance

Excessive rotation

Errors in calculating the specific weight of

gas

Adjust it with the damper.

Replace the V-belt pulley.

Reduce the rotational speed.

7-1