MAINTENANCE

63

515SS MM419 (4--96)

D

The sweeper assembly lowers and

raises.

D

The recovery tank auto-fill valve turns

on and off.

4. If the electrical system passes the

self-diagnostic test, an OK message will

appear on the control panel display.

If the self-diagnostic test finds an error in the

system, an error message will appear on the

control panel display. Note the error

message displayed, and contact the service

personnel.

5. Turn off the diagnostic by turning off the

machine power.

ELECTRIC MOTORS

The carbon brushes on the vacuum fan motors

should be inspected every 500 hours of machine

operation. The brush drive motors and propelling

motor should be inspected every 1000 hours of

operation.

PROPELLING CIRCUIT

The propelling circuit is a transistorized controller.

It controls the forward and reverse speed of the

machine and is located in the controller panel.

The circuit cannot be serviced by the user -- only

trained personnel should be allowed to work on it.

Do not steam clean or spray the panel with water

because the electrical system may be damaged.

NOTE: A static discharge grounding strap should

be used when servicing the electronic circuitry.

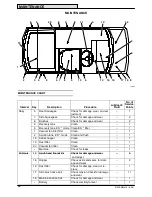

SCRUB HEAD

The machine can be equipped with either a

MaxPro

t

1000 or MaxPro

t

1200 scrub head.

The MaxPro

t

1000 is the standard two disk

brush scrub head. The optional MaxPro

t

1200 is

a three disk brush scrub head. The scrub head

floor skirts control water spray from the brushes.

10734