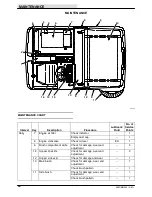

MAINTENANCE

57

385D MM305 (3--97)

Interval

Key

Description

Procedure

Lubricant/

Fluid

No. of

Service

Points

50 Hours

13

Main brush

Rotate end-for-end

--

1

50 Hours

6

Fuel pipes and clamps

Check for tightness and wear

--

1

100 Hours

6

Engine crankcase

Change oil and filter

EO

1

100 Hours

4

Engine fan belt

Check tension

--

1

10

Hopper dust filter

Check for damage, clean or re-

place

--

1

3

Radiator

Clean core exterior

--

1

3

Radiator

Check coolant level

WG

1

2

Hydraulic fluid reservoir

Check fluid level

HYDO

1

1

Rear tire

Check pressure

--

1

8

Main brush and hopper

seals

Check for damage or wear

--

8

200 Hours

3

Radiator hoses and clamps Check for tightness and wear

--

2

200 Hours

15

Parking brake

Check adjustment

--

1

14

Brake pedal

Check and adjust travel

--

1

1

Rear wheel support bear-

ings

Lubricate

SPL

1

11

Side brush guard

Rotate 90

_

--

1

400 Hours

9

Front wheel bearings

Check, lubricate, and adjust

SPL

2

400 Hours

6

Fuel filter

Replace cartridge

--

1

17

Fuel tank

Remove sediment

--

1

3

Cooling system

Flush

WG

1

800 Hours

2

Hydraulic reservoir

Replace hydraulic breather

--

1

800 Hours

2

Hydraulic reservoir

Replace suction strainer

--

1

Change hydraulic fluid

HYDO

1

5

Hydraulic fluid filter

Change filter element

--

1

2

Hydraulic hoses

Check for wear and damage

--

31

1

Propelling motor

*Torque shaft nut

--

1

1

Rear wheel

*Torque wheel nuts

--

1

16

Battery

*Clean and tighten battery cable

connections

--

1

LUBRICANT/FLUID

EO

Engine oil, SAE--CC/CD rated

. . . .

HYDO

Tennant Company or approved hydraulic fluid

.

WG

Water and permanent-type ethylene glycol anti-freeze, --34

_

C (--30

_

F)

. . .

SPL

Special lubricant, Lubriplate EMB grease (TENNANT part no. 01433--1)

. . .

NOTE: Also check procedures indicted (*) after the first 50-hours of operation.