MAINTENANCE

242E MM243 (5---92)

3-12

8. Stop the machine.

9. Raise the rear of the machine, remove the jack

stands, and lower the machine.

10. Fill the hydraulic fluid reservoir with new,

approved hydraulic fluid.

11. Check for system leaks. Correct any leaks

found.

12. Replace the hydraulic fluid filter after the first

hour of operation.

DIRECTIONAL PEDAL

The directional pedal controls the flow of hydraulic

fluid to the hydraulic drive motor. The pedal has

three positions --- “forward,” “neutral,” and “reverse.”

The “forward” and “reverse” positions sends

hydraulic fluid to the drive motor to propel the

machine.

The “neutral” position is the position in which the

propelling pump sends no hydraulic fluid to the

propelling motor. The machine should not creep

when the “neutral” position is correctly adjusted.

Adjust the directional pedal linkages whenever the

machine creeps or after replacing the hydraulic

propelling pump or pump linkages.

TO ADJUST DIRECTIONAL PEDAL NEUTRAL

POSITION

1. Turn off the machine and set the machine

parking brake.

FOR SAFETY: Before Leaving Or Servicing

Machine; Stop On Level Surface, Set Parking

Brake, And Turn Off Machine And Remove Key.

2. Block the machine tires and jack up the rear of

the machine at the designated locations.

FOR SAFETY: When Servicing Machine, Block

Machine Tires Before Jacking Machine Up.

3. Block up the machine with hack stands near

the designated locations. Make sure the rear

tire clears the floor by 2 in (50 mm) and all

obstacles within a 24 in (610 mm) radius.

FOR SAFETY: When Servicing Machine, Jack

Machine Up At Designated Locations Only. Block

Machine Up With Jack Stands.

4. Start the machine.

5. Move the directional pedal in the “forward”

position and release it. The rear wheel should

stop rotating as soon as the pedal is released.

Turn off the machine and loosen the screws

mounting the spring bracket to the machine

frame and to adjust as required.

A

B

C

05671

DIRECTIONAL PEDAL ADJUSTMENT

A. Spring Bracket

B. Spring

C. Directional Pedal

6. Move the directional pedal into the “reverse”

position and release it. The rear wheel should

stop rotating as soon as the pedal is released.

Turn off the machine and loosen the screws

mounting the spring bracket to the machine

frame and to adjust as required.

7. Tighten the mounting screws of the spring

bracket.

8. Raise the rear of the machine, remove the jack

stands, and lower the machine.

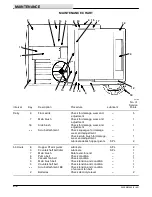

Summary of Contents for 242E

Page 1: ......

Page 10: ...SPECIFICATIONS 242E MM243 9 89 1 2 ...

Page 14: ...SPECIFICATIONS 242E MM243 9 89 1 6 ...

Page 16: ...OPERATION 242E MM243 5 92 2 2 ...

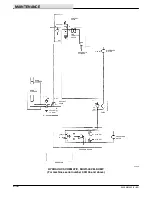

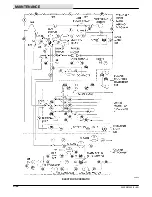

Page 62: ...MAINTENANCE 242E MM243 5 92 3 22 05805 ELECTRIC SCHEMATIC ...

Page 88: ...MAINTENANCE 242E MM243 5 92 3 48 ...

Page 90: ...APPENDIX 242E MM243 9 89 4 2 ...