1

2

3

4

Don't use extensions on the handle.

The torque measurement will be

inaccurate and the tool could

become damaged.

STOP

applying torque when you hear and

feel a click. This means you’ve reached the

desired torque value.

2

Click!

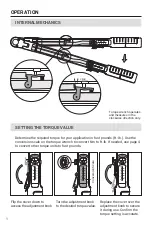

APPLYING TORQUE

OPERATION

For off-axis tools, like a crowfoot

wrench, calculate a leverage

adjustment on page 5.

Attach a drive tool to the drive tang.

The flex joint provides clearance for

working around obstacles but, when

flexed, can reduce accuracy by up to

4 percent due to the offset from the

plane of rotation.

Engage the drive tool on the fastener

or fitting. For the most accurate

reading, the ratchet head must be

parallel with the wrench body.

Grip the center of the handle and apply

torque

SLOWLY

in a clockwise direction.

Don't use the torque wrench on

electrical circuits. The handle

doesn’t provide insulation from

electrical current.

Center of Handle

Parallel Flexed

Flexed