å

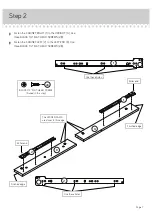

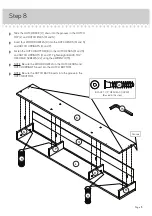

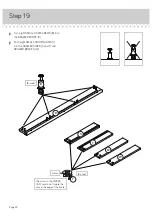

Slide the HUTCH BACK (Q) down into the grooves in the HUTCH

TOP (L) and HUTCH ENDS (M and N).

å

Insert four WOOD DOWELS (9) into the HUTCH ENDS (M and N)

and HUTCH UPRIGHTS (O and P).

å

Fasten the HUTCH BOTTOM (K) to the HUTCH ENDS (M and N)

and HUTCH UPRIGHTS (O and P). Tighten eight BLACK 1-1/2"

HEX HEAD SCREWS (22) using the L-WRENCH (15).

å

NOTE: Be sure the WOOD DOWELS in the HUTCH ENDS and

HUTCH UPRIGHTS insert into the HUTCH BOTTOM.

å

NOTE: Be sure the HUTCH BACK inserts into the groove in the

HUTCH BOTTOM.

Step 8

Page 13

M

N

P

O

K

Q

Groove

9

BLACK 1-1/2" HEX HEAD SCREW

(8 used in this step)

15

9

L

22