Step 17

Page 21

D48

D49

å

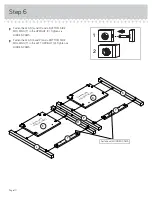

Push a FILE GLIDE (4B) onto the DRAWER RIGHT SIDE (D48).

å

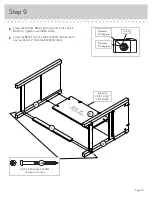

Slide the FILE RODS (7B) into the FILE GLIDE (4B) on the

DRAWER RIGHT SIDE (D48).

å

Slide another FILE GLIDE (4B) onto the other end of the

FILE RODS (7B), then press this FILE GLIDE over the

DRAWER LEFT SIDE (D49).

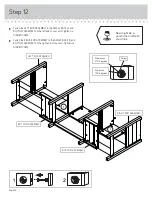

Insert the FILE RODS into the holes

of your choice in the FILE GLIDES,

depending on your fi le sizes.

4B

7B

7B

4B

Almost time to

celebrate! With a nap.