Technosoft 2018

40

iPOS4808 VX Technical Reference

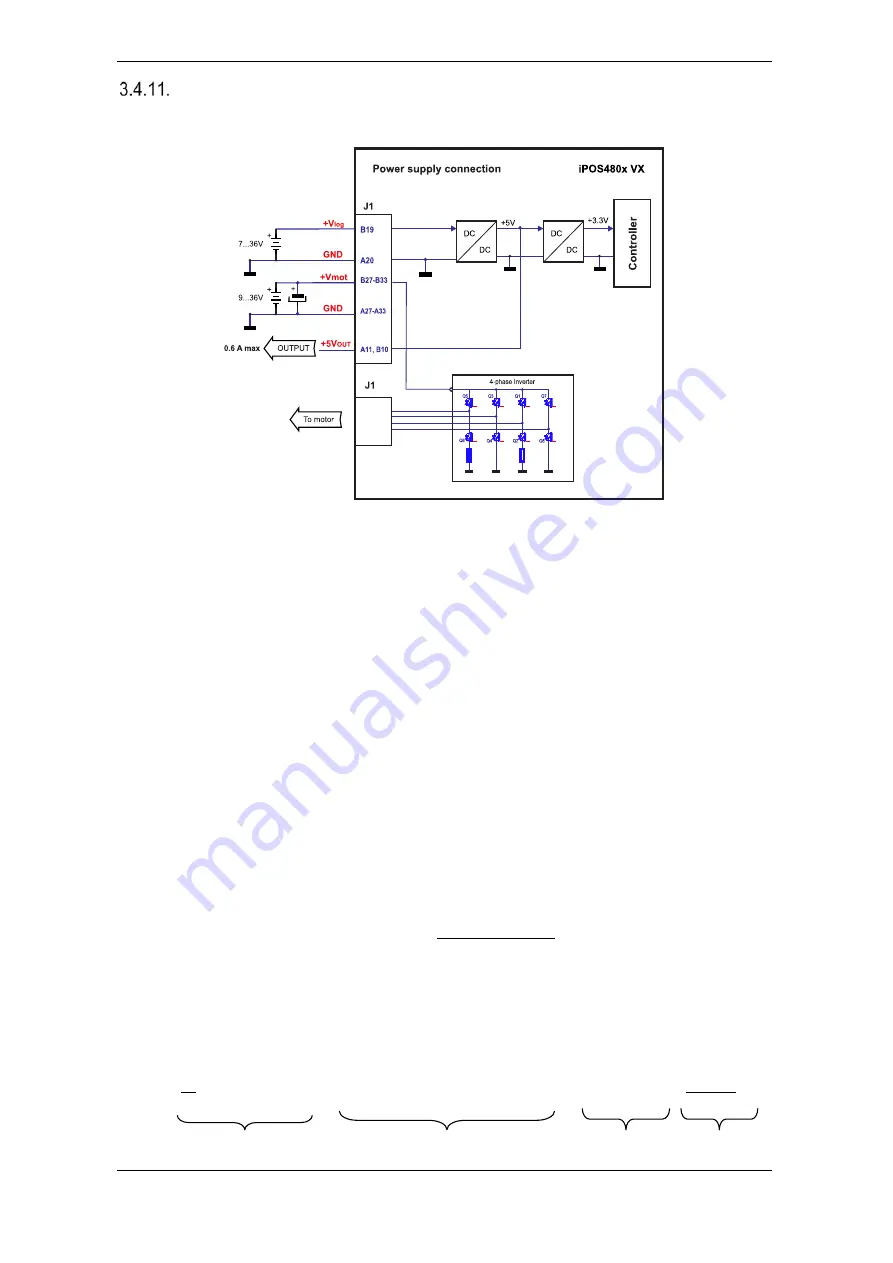

Power Supply Connection

3.4.11.1 Supply Connection

Figure 3.25. Supply connection

3.4.11.2 Recommendations for Supply Wiring

Always provide a nearby capacitor on the motor supply lines. The capacitor should be located within

10cm of the iPOS4808 edge connector, max. 20cm. The minimum recommended capacitance is

330µF for iPOS4808, always rated at the appropriate voltage.

Use short, thick wires between the iPOS4808 and the motor power supply. Connect power supply

wires to all the indicated pins. If the wires are longer than 2 meters, use twisted wires for the supply

and ground return. For wires longer than 20 meters, add a capacitor of at least 2,2

00μF (rated at

an appropriate voltage) right on the terminals of the iPOS4808.

3.4.11.3 Recommendations to limit over-voltage during braking

During abrupt motion brakes or reversals the regenerative energy is injected into the motor power

supply. This may cause an increase of the motor supply voltage (depending on the power supply

characteristics). If the voltage bypasses 53V, the drive over-voltage protection is triggered and the

drive power stage is disabled. In order to avoid this situation you have 2 options:

Option 1. Add a capacitor on the motor supply

big enough to absorb the overall energy flowing

back to the supply. The capacitor must be rated to a voltage equal or bigger than the maximum

expected over-voltage and can be sized with the formula:

2

2

2

NOM

MAX

M

U

U

E

C

−

×

≥

where:

U

MAX

= 53V is the over-voltage protection limit

U

NOM

is the nominal motor supply voltage

E

M

= the overall energy flowing back to the supply in Joules. In case of a rotary motor

and load, E

M

can be computed with the formula:

F

M

d

d

Ph

2

M

final

initial

L

M

2

M

L

M

M

T

2

t

t

R

3I

)

h

-

)g(h

m

(m

)

J

(J

2

1

E

ϖ

ϖ

−

−

+

+

+

=

Kinetic energy

Copper losses Friction losses

Potential energy