8

17.

Insert o-ring (10) into outlet block (11).

18.

Re-install outlet block (11) to fluid housing (6).

19.

Lubricate o-ring (17) with Bimba HT-99, or equivalent.

20.

Thread the air cylinder/spool assembly into fluid housing/outlet block

assembly. Make sure not to cross thread both parts.

7.2

Cleaning and seal replacement for air cylinder:

1.

Hold the fluid housing (6) and rotate the air cylinder (18) counterclockwise.

When completely un-threaded, pull the two valve segments straight apart to

separate.

2.

Remove end cap (19) by rotating it in counterclockwise direction.

3.

Using the snap ring pliers, remove the retaining ring (2).

4.

Pull the spool assembly (5) straight out from the air cylinder (18).

5.

Remove the compression spring (4).

6.

Using the snap ring pliers, remove the retaining ring (7).

7.

Remove the nylon washer (15) from the air cylinder.

8.

Using o-ring removal tool, remove o-ring (16).

9.

Replace all o-rings if necessary.

10.

Lubricate all o-rings with Bimba HT-99, or equivalent.

11.

Re-install o-ring (16).

12.

Re-install nylon washer (15) and secure with retaining ring (7) Re-install

compression spring (4) into air cylinder (18).

13.

Thread the air cylinder into fluid housing/outlet block assembly making sure

not to cross thread both parts.

14.

Re-install spool assembly (5) and secure with retaining ring (2).

15.

Re-install end cap (19).

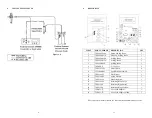

13

12

19

18

17

16

15

1

2

3

5

4

6

8

7

9

10

11

14

Figure 5.0

9

8.

SPARE PARTS

Valve Rear Section

ITEM PART

NUMBER DESCRIPTION

QTY

1 TSD1120-2

Retaining

Ring,

Small

1

2 TSD1109-45

Nylon

Washer

1

3 TD1400-006A O-Ring,

Buna

1

4 TSD1400-013A O-Ring,

Buna

1

5 TSD1150-5

Spring

1

6 5322-000-001 Spool/Piston

Assembly

1

7 TSD1400-208A Piston

O-Ring,

Buna

1

8 TSD1120-15

Retaining

Ring,

Large

1

9

TSD1400-017A

End Cap O-Ring, Buna

1

10 5520-000-007 End

Cap

1

11

TSD1002-37

Air Fitting, 4mm

1

12

A0100478

Air Hose/Connector Assembly, 4mm

1

13 5520-000-001 Air

Cylinder

1

14 918-000-048

Mounting

Bracket

1

15 TSD1106-36

Mounting

Screw

1

Recommended lubricant:

All o-rings & seals must be

lubricated with Bimba HT-99,

or equivalent.