2

3

Installation Instructions

By following these instructions carefully, your new hoist can be

assembled quickly to give safe, smooth and efficient operation

and an extended, trouble-free life.

Note: Use lifting equipment or extra people to lift & handle the

heavy parts.

1. The hoist must be installed under cover on a flat concrete

floor of minimum tensile strength Grade 25 MPa and minimum

thickness 100 mm with at least one layer of F72 reinforcing

mesh. The hoist must not be installed in a location where it is

exposed to the weather or explosive or flammable materials.

If the floor is not satisfactory, a new concrete base with a

minimum area of 3.7 x 1.6 m will need to be laid and allowed to

cure for one month before installing the hoist.

2. Install a mains isolator switch on a wall or column next to

where the hoist power column will be situated.

Note: This must be done by a qualified electrician.

For a three phase hoist, the power supply must be 415V, 50 Hz,

rated to carry 15A full load current and 33A inrush. The wiring

must be 3 core plus earth and a minimum 7-strand, 2.5 mm²

cross sectional area copper. For long runs larger wiring may be

required.

For a single phase hoist, the power supply must be 240 V, 50 Hz,

rated to carry 23A full load current and 132A inrush. The wiring

must be 2 core plus earth and a minimum 7-strand, 4 mm²

cross sectional area copper. For long runs larger wiring may be

required.

3. Unpack the hoist and place the base frame on the floor in the

desired position to allow easy access for vehicles and leaving a

clear 600 mm wide gap around the hoist for operator access.

Note: The drive column goes on the end of the base frame that

has the angle iron fitted inside (refer Fig.1)

Inspect the floor where the four hold-down bolts will go. The

hold-down bolts must not be installed within 200 mm of any

edge, crack or other fastener in the floor.

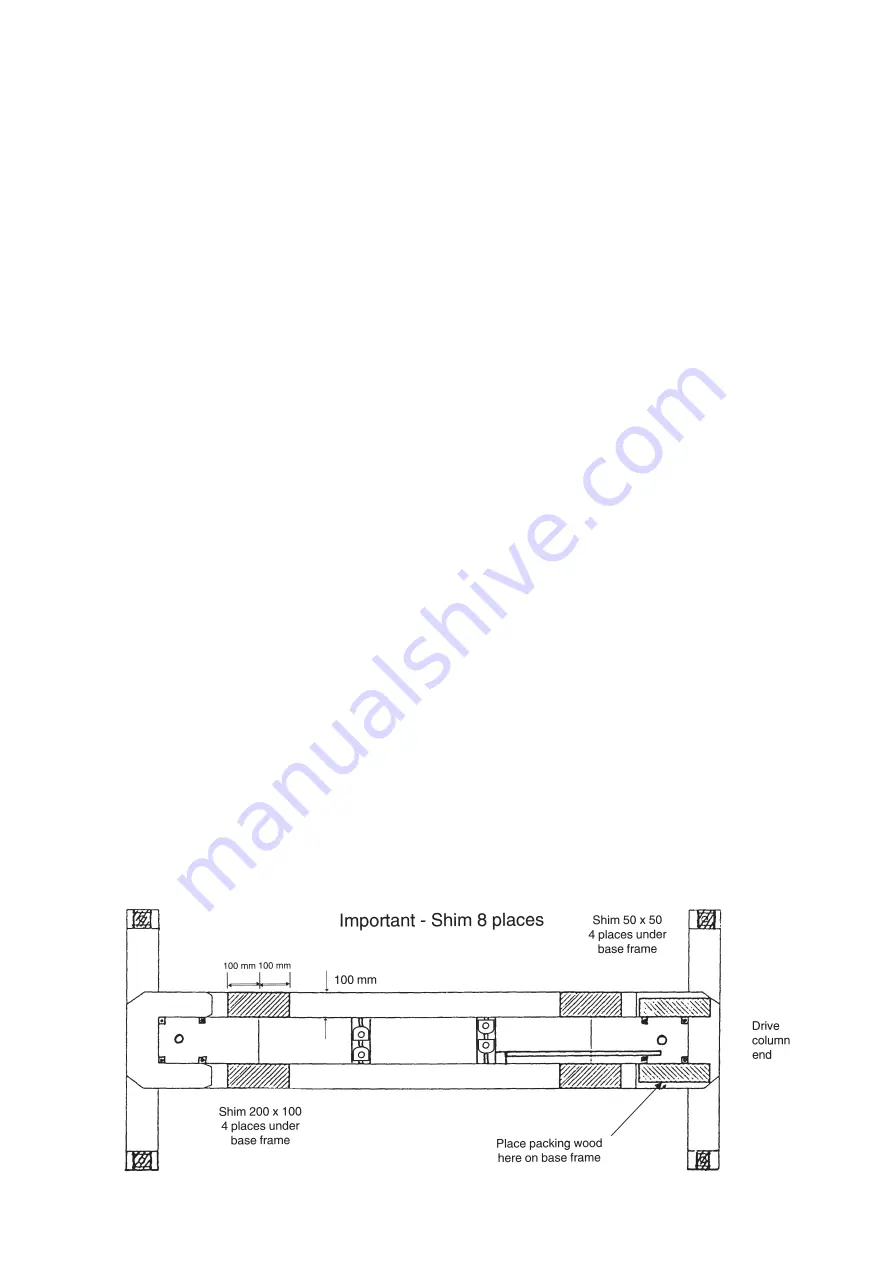

4. Level the base frame by adding 50 mm square metal shims,

with a 20 mm diameter hole in the centre, under the base frame

at the four hold-down bolt holes. When level, add 200 x 100 mm

metal shims under the base frame, as shown in Fig.1, to remove

any gap but without lifting the four corners of the base frame off

their shims.

Note: the maximum permissible gap between the base frame

and shims is 0.5 mm.

5. Drill and fit four hold-down bolts. The bolts must be 16

mm thread diameter and fitted in accordance with the

manufacturer’s instructions:

Approved expanding-type masonry anchors – Ramset Trubolt

T16125 and Hilti HSA stud anchor M16 x 140/25.

Note: The bottom edge of the expansion sleeve on the masonry

anchor must be a minimum of 75mm deep in the concrete when

tightened. If the base has been shimmed up a large amount,

longer anchors will be required to ensure this depth is reached.

Some authorities may not approve expanding type masonry

anchors. Approved adhesive masonry anchors: Ramset Chemset

capsule CHEM 16 and stud bolt M 16190 and Hilti adhesive

cartridge HEAM 16 x 125 and anchor rod HASM 16 x 190.

Note: These fasteners require a minimum concrete thickness

and hole depth of 125 mm.

6. Lay the drive chain in the base frame so that it runs between

the chain rollers as shown in Fig.2.

Note: The joining link spring clip must be on top.

7. At the drive column at the end of the base frame lay two 38

mm thick x 400 mm long pieces of packaging wood along each

leg of the U-shaped plate as shown in Fig.1. Position the drive

column so it is laying on its back (as packed) with the column

base plate on top of the wood.

8. Secure the chain limit switch (which comes out of the bottom

of the column) out of the way, then stand the column up on

the pieces of wood. Position the column so the bolt holes in the

column and base frame roughly line up. Make sure the column

is stable on the wood and is being held at all times to prevent it

falling over.

9. Lay the chain limit switch and wiring in the base frame,

with the wiring lying inside the angle iron and the switch on

its mounting plate as in Fig.2. Reach under the column base

plate and fit the chain on to the sprocket (it may be easier if the

column is tilted back slightly). Keep holding the chain tight on

the sprocket. Tilt the column from side to side and remove the

pieces of packing wood (be careful it does not fall).

10. Bolt the column down using two M16 x 50 mm long and

two M10 x 35 mm long high tensile bolts. Leave the M16 bolts

undone about 4 mm (two turns). Fully tighten the M10 bolts

with a ring or socket spanner, then tighten the M16 bolts fully

with a torque wrench to 200NM (147 ft lbs).

Note: The bolts must be high tensile, identified by the marking

‘8.8’ on the head of the bolts.

Fig. 1