2-16

EM18-33010A

2. MAJOR UNIT REPLACEMENT

Fig. 2-27

(Revision Date Sep. 29, ’95)

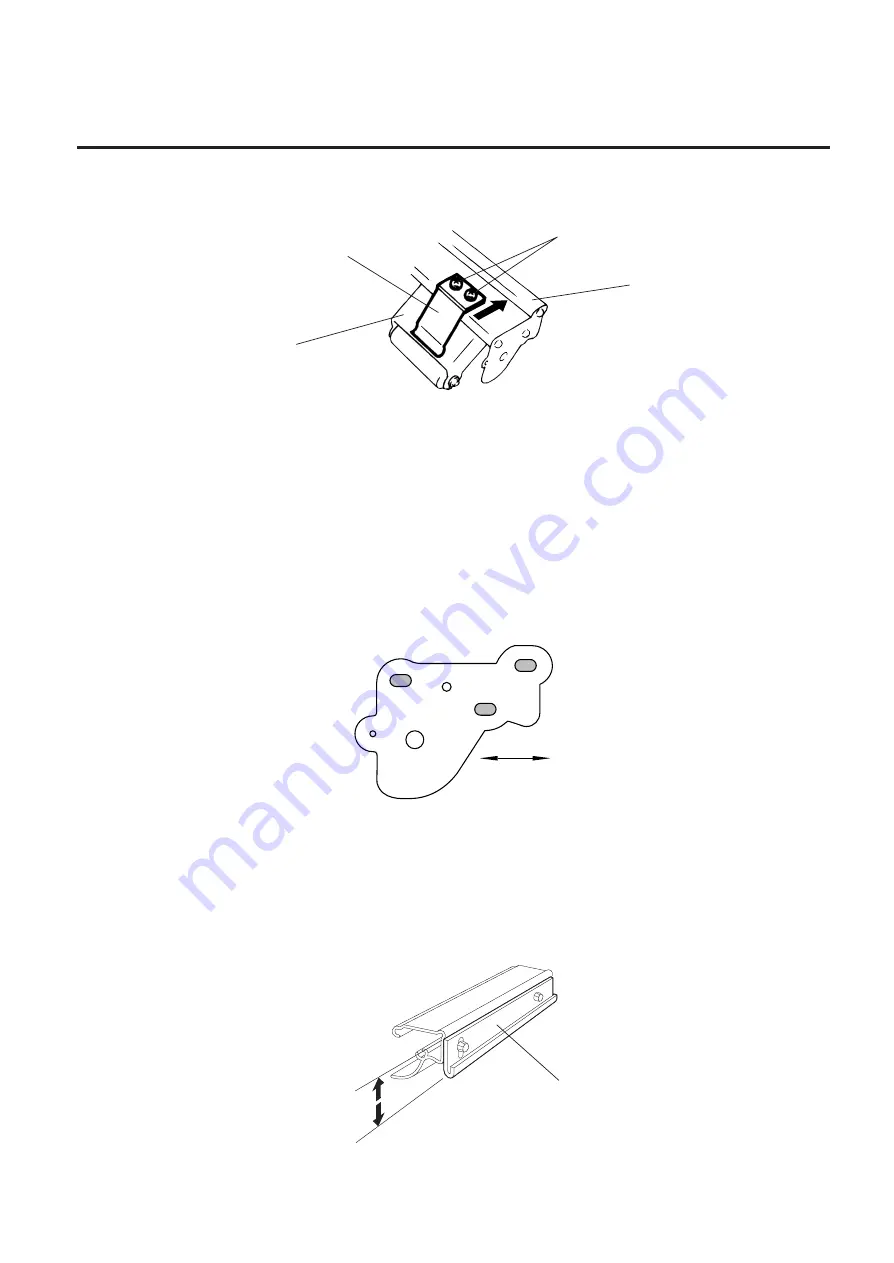

2.10 REPLACING THE PINCH ROLLER SHAFT ASS’Y

2.11 CORRECTING SKEW PRINTING

●

If media still skews after adjusting the pinch roller shaft ass’y with the jig, follow the procedure below

to correct the skew problem.

1.

Check if the media skews right or left.

2.

Loosen the B-4x12 screw to move the pinch roller cover to the front or rear of the printer depending

on the skew direction.

3.

Turn the head lever clockwise to lock the pinch roller shaft ass’y. Attach the spring plate to the pinch

roller frame with the two SM-4x8B screws, pushing the spring plate toward the rear of the printer.

NOTE: Check that the pinch roller shaft ass’y moves up and down smoothly when turning the head

lever clockwise and counterclockwise.

4.

Install the media guide plate to the printer so there is a 1.5 to 2.5 mm gap between the media guide

plate and the printer block base.

When the media skews right, move the pinch roller cover to the front.

When the media skews left, move the pinch roller cover to the rear.

●

If a paper skew problem should occur when using rolls would with labels facing outside after

completing the modification, adjust the paper guide as follows.

*

In case the label skews to the right side of the print head, move the guide downward.

*

In case the label skews to the left side of the print head, move the guide upward.

Fig. 2-28

Fig. 2-26

Front

Rear

SM-4x8B

Pinch Roller Frame

Pinch Roller Shaft Ass’y

Spring Plate

Guide Plate