CABLES

To adjust the standard cable operating the spools, undo

the two socket head cap screws securing the clamp

plate to the valve. Undo the lock nut on the end of the

cable and rotate the adapter tube until the spool

operates correctly.

To adjust the flow control cable, remove the actuator

handle from the mounting bracket by partly removing the

3 long studs. Release the cable lock nut at the valve

adapter end and rotate the actuator and cable outer 1

complete turn. Operate the bed chain to check the

required adjustment has been achieved before

reassembling the actuator into the mounting bracket.

HYDRAULIC VALVE

Before attempting to dismantle any of the hydraulic

system, the tailgate and deflectors must be fully

lowered to prevent injury from the unexpected

lowering of these components.

To split the valve slices, withdraw the three long studs

through the valve. The positions of the seals are shown

in the parts book diagram. When reassembling the

valve, the studs should be tightened to a torque of 13.5

Nm (10 lb.ft). If over tightened then the spools may jam.

If contaminated oil enters the bypass valve in the flow

control slice, it may jam open causing the hydraulic

circuit to fail. The bypass valve is found on the lower

sloping face of the flow control valve below the pressure

relief valve. To clear the blockage, undo the cap,

carefully making sure the return spring is not lost. Using

a pair of long nosed pliers withdraw the spool from the

valve body. Clear any contamination and refit the spool,

which should move freely. Refit the return spring and

cap.

Contamination may also jam open the pressure relief

valve in the flow control slice. To clear, remove the relief

valve from the body and clear any contamination.

SLIP CLUTCH

If the clutch slips repeatedly for no apparent reason

there are a number of things to be checked:

Firstly check that the clutch linings do not show signs of

damage or excessive wear. If so, they should be

replaced. When new they are 3mm. (1/8") thick.

Also make sure that the compressed spring length is set

to give the correct torque setting – see PTO shaft parts

list.

If the clutch continues to slip it should be adjusted as

follows.

1. Remove the guard fitted to the rotor gearbox.

2. Fit the PTO shaft with the slip clutch at the machine

end.

3. Insert a piece of wood through the discharge chute

and position it such that it prevents the rotor from

turning.

4 Insert a steel bar through the rear PTO yoke and use

a spring balance to obtain the correct torque setting.

The clutch should just slip at a torque of 1200 Nm.

(900 lb.ft.) - equal to a force of 1000N. at 1.2 metre

(225 lb. at 4 feet) from the centre of the yoke. Adjust

the clutch as necessary using the eight spring loaded

clamp bolts.

WHEEL REPLACEMENT

If it is necessary to remove a wheel, place a jack

underneath the axle beam, loosen the wheel nuts and

raise the machine until the wheel can be removed.

Place an axle stand underneath the machine before

removing the wheel. Refit the wheel and tighten the

wheel nuts.

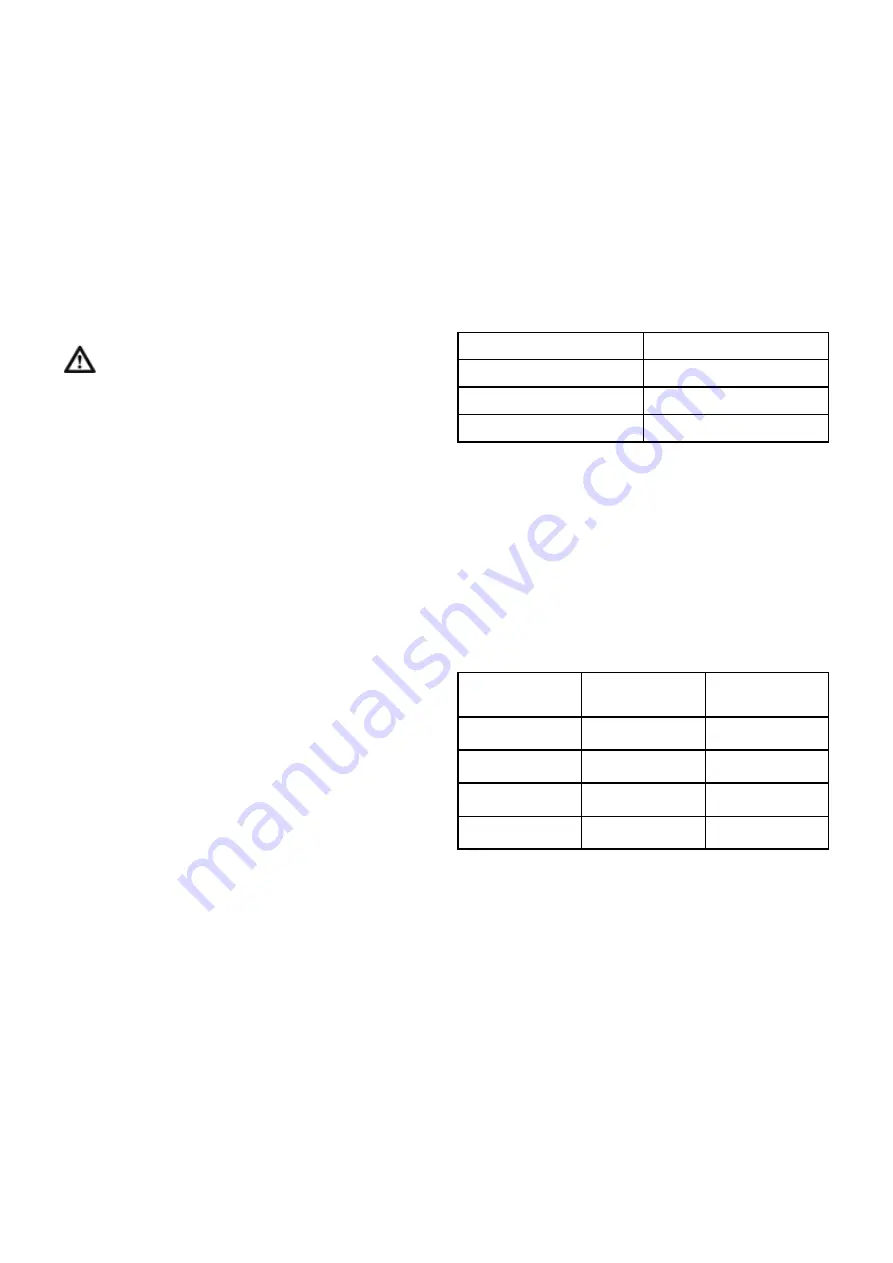

WHEEL NUTS

Before using a new machine and daily during use, check

the wheel nuts are tight. The recommended torque is

shown in table 3.

Table 3. Wheel nut torque settings.

Once the nuts are allowed to work loose, it may be

found impossible to keep them tight and new nuts and

studs will be required to overcome the problem. In

extreme cases, damage to the wheel rims and hubs

may result.

TYRE PRESSURES

Check tyre pressures regularly inflating to the pressures

shown in the following table. Over inflation can be

dangerous.

Table 4. Tyre Pressures.

LUBRICATION

Good quality semi-solid grease should be applied to the

following grease points:

Every 4 weeks:

Oil PTO shaft spring plungers

Every 2 weeks:

Swivel chute ring gear (4 nipples)

PTO shaft joints - (2 nipples)

PTO guard bearings (where fitted)

PTO shaft sliding members

Twice weekly:

Bed chain bearings (4 nipples)

Crossbeater bearings (4 nipples)

Shearbolt sprocket bearing (1 nipple)

Bale restraint pivot bearings (2 nipples)

Wheel stud size

Torque Nm (lb.ft)

8080 ( 5 stud )

200 ( 150 )

8080 ( 6 Stud )

400 ( 320 )

9090 ( 6 Stud )

400 ( 320 )

Tyre Size

8080 Pressure

bar (psi)

9090 Pressure

bar (psi)

10.0/80-12

2.4 ( 35 )

- - - - -

10.0/75-15.3

2.0 ( 29 )

- - - - -

11.5/80-15.3

1.2 ( 17 )

5.0 ( 73 )

12.5/80-15.3

1.2 ( 17 )

5.2 ( 75 )

9

Summary of Contents for Tomahawk 8080S

Page 34: ...32 HYDRAULIC HOSES...