NOTE

i

408-8881

2 of 3

Rev A

2. Insert the indenter into the stationary jaw so that

the chamfer faces outward.

3. Place two retaining pins through the tool frame

and indenter.

4. Thread, but do not tighten, a die retention screw

through the center hole in the jaw so that the die is

held in place.

5. Insert the anvil into the movable jaw so that the

chamfer faces outward.

6. Place two retaining pins through the tool frame

and anvil.

7. Thread, but do not tighten, a die retention screw

through the center hole in the jaw so that the die is

held in place.

8. Slowly close the tool handles, allowing the dies to

mate and align. Continue closing the handles until

the ratchet makes the fifth “click”, then tighten both

die retention screws.

The ratchet has detents with audible “clicks” as the

handles are closed. The ratchet releases on the

sixth “click”.

4. CRIMPING PROCEDURE

NOTE

i

This tool is provided with a crimp adjust feature.

Initially, the crimp height should be verified as

specified in Figure 3. Refer to Section 5, CRIMP

HEIGHT INSPECTION, and Section 6, CRIMP

HEIGHT ADJUSTMENT, to verify crimp height

before using the tool to crimp desired contacts and

wire sizes.

Refer to the table in Figure 1 and select wire of the

appropriate size and insulation diameter. Strip the wire

to the length specified in Figure 1, taking care not to

nick or cut wire strands. Select an applicable contact

and identify an appropriate crimp section according to

the wire size markings on the tool.

NOTE

i

1. Squeeze the tool handle together until the ratchet

releases. Allow the tool handles to open FULLY.

Keep wire pins in strip form during

crimping procedure.

!

CAUTION

2. Holding the wire pins by the strip, place the wire

pin on the end of the strip in the appropriate crimp

section.

3. Position the wire pin so that it is centered in the

crimp section and squeeze the tool handles

together until the ratchet engages sufficiently to

hold the wire pin in place without deforming it.

Make sure that both sides of the wire barrel are

started evenly into the crimping section. Do NOT

attempt to crimp an improperly positioned contact.

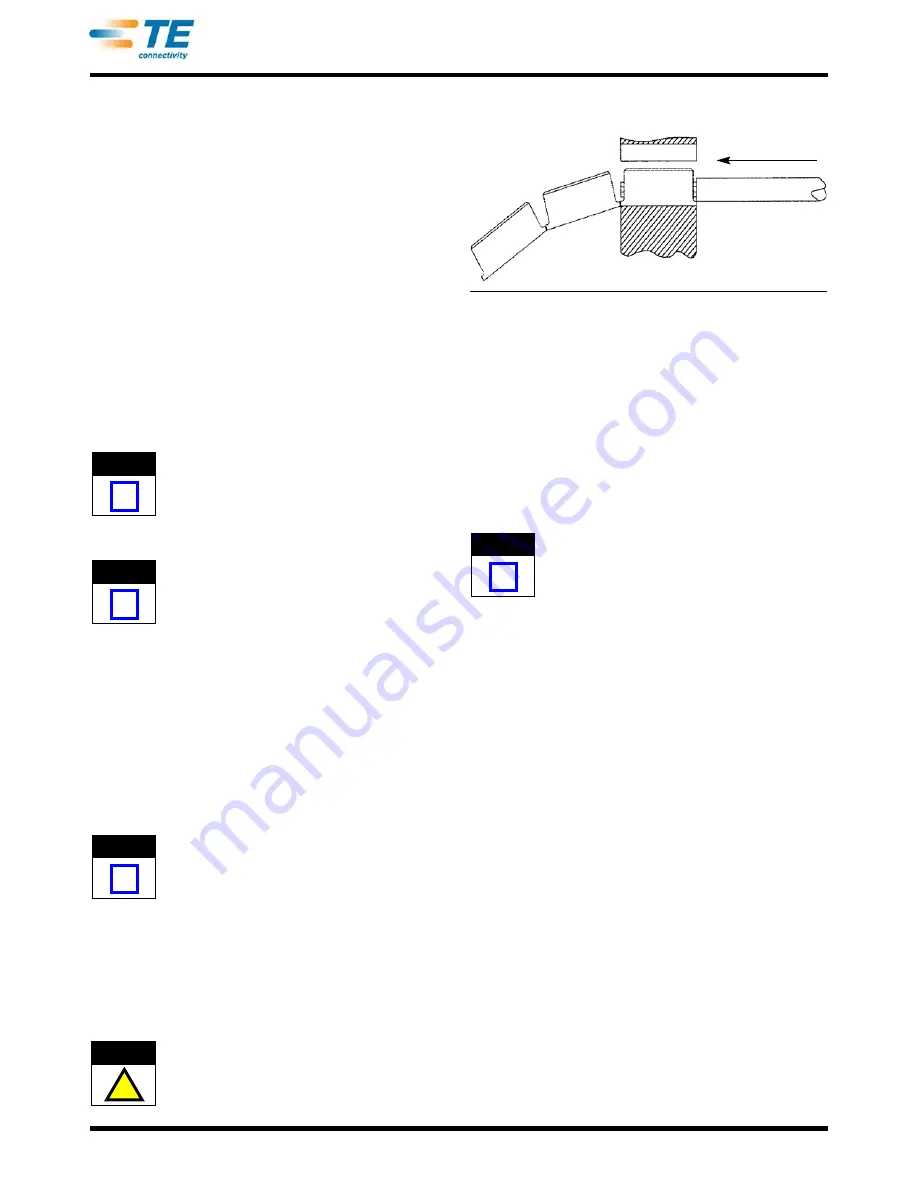

Wire Pin Shown in Strip Form

Wire Inserted in

This Direction

Figure 2

NOTE

i

4. Insert stripped wire into wire pin. See Figure 2.

5. Holding the wire in place, squeeze tool handles

together until ratchet releases. Allow tool handles to

open and remove the crimped contact.

6. Break the crimped contact free from the rest of

the strip by bending the contact back and forth.

7. Check the contacts crimp height as described in

Section 5, CRIMP HEIGHT INSPECTION. If

necessary, adjust the crimp height as described in

Section 6, CRIMP HEIGHT ADJUSTMENT.

Damaged wire pins should not be used. If damaged

wire pins are evident, they should be replaced with

new ones.

5. CRIMP HEIGHT INSPECTION

Crimp height inspection is performed using a

micrometer with a modified anvil, commonly referred

to as a crimp height comparator. Refer to instruction

sheet 408-7424 for detailed information on obtaining

and using a crimp height comparator.

Proceed as follows:

1. Refer to Figure 1 and select a wire (maximum

size) for each crimp section listed.

2. Refer to Section 4, CRIMPING PROCEDURE,

and crimp the contact(s) accordingly.

3. Using the crimp height comparator, measure the

wire barrel crimp height listed in Figure 3. If the

crimp height conforms to that shown in the table,

the tool is considered dimensionally correct. If not,

the tool must be adjusted. Refer to Section 6,

CRIMP HEIGHT ADJUSTMENT.