114-13233

Rev B

2

of 13

2.

REFERENCE MATERIAL

2.1.

Revision Summary

Updated document to corporate requirements and updated text in Paragraph 2.2

2.2.

Customer Assistance

Reference Product Base Part Numbers 1445692, 2000314, and Product Code H723 are representative

numbers of Quadrax DSub Connectors and Contacts. Use of these numbers will identify the product line and

help you to obtain product and tooling information. Such information can be obtained through a local TE

Representative, by visiting our website at www.te.com, or by calling PRODUCT INFORMATION or the

TOOLING ASSISTANCE CENTER at the numbers at the bottom of page 1.

2.3.

Drawings

Customer Drawings for product part numbers are available from the service network. If there is a conflict

between the information contained in the Customer Drawings and this specification or with any other technical

documentation supplied, the information contained in the Customer Drawings takes priority.

2.4.

Manuals

Manual 402-40 is available upon request and can be used as a guide to soldering. This manual provides

information on various flux types and characteristics with the commercial designation and flux removal

procedures. A checklist is included in the manual as a guide for information on soldering problems.

2.5.

Specifications

and Qualification Test Report

provides product performance and test

information for the Quadrax Contacts. Test Specification

provides solderability requirements and

evaluation methods. The DSub connectors are tested to Product Specification

. Application

Specification

provides crimping procedures and requirements for the pin and socket contacts.

2.6.

Instructional Material

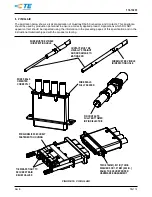

The following list includes available instruction sheets (408-series) that may provide assembly procedures for

product, operation, maintenance and repair of tooling.

Document Number

Document Title

Coaxial Cable Stripper Cable Kits 603995

Checking Terminal Crimp Height or Gaging Die Closure

Application Tooling for Screw-Machine Contacts

3.

REQUIREMENTS

3.1.

Safety

Do not stack product shipping containers so high that the containers buckle or deform.

3.2.

Limitations

The connectors are designed to operate within a temperature range of -65° to 125°C [-85° to 257°F].

NOTE

Temperature rating of the cable must be considered when determining operating temperature of the connector and cable

assembly.

3.3.

Storage

A.

Ultraviolet Light

Prolonged exposure to ultraviolet light may deteriorate the chemical composition of components used in

the contacts or connectors.