409-1950

Rev G

19

of 22

Draining, Flushing, and Refilling the Hydraulic Fluid Reservoir

The frequency of oil changes depends upon the general working conditions, severity of use, and overall

cleanliness and care of the pump. It is recommended to drain, flush, and refill the reservoir of the pump

with an approved hydraulic oil after approximately every 300 hours of operating the pump as follows:

Depress the DUMP switch to release the pressure from the system, then DISCONNECT the pump from

the power supply.

NOTE

For 69120-2, drain the reservoir using the drain plug at the bottom of the reservoir.

Clean the pump exterior. The pump exterior must be clean before the motor and pump assembly is

removed from the hydraulic fluid reservoir.

Remove the 10 screws securing the motor and pump assembly to the hydraulic fluid reservoir. Remove

the motor and pump assembly.

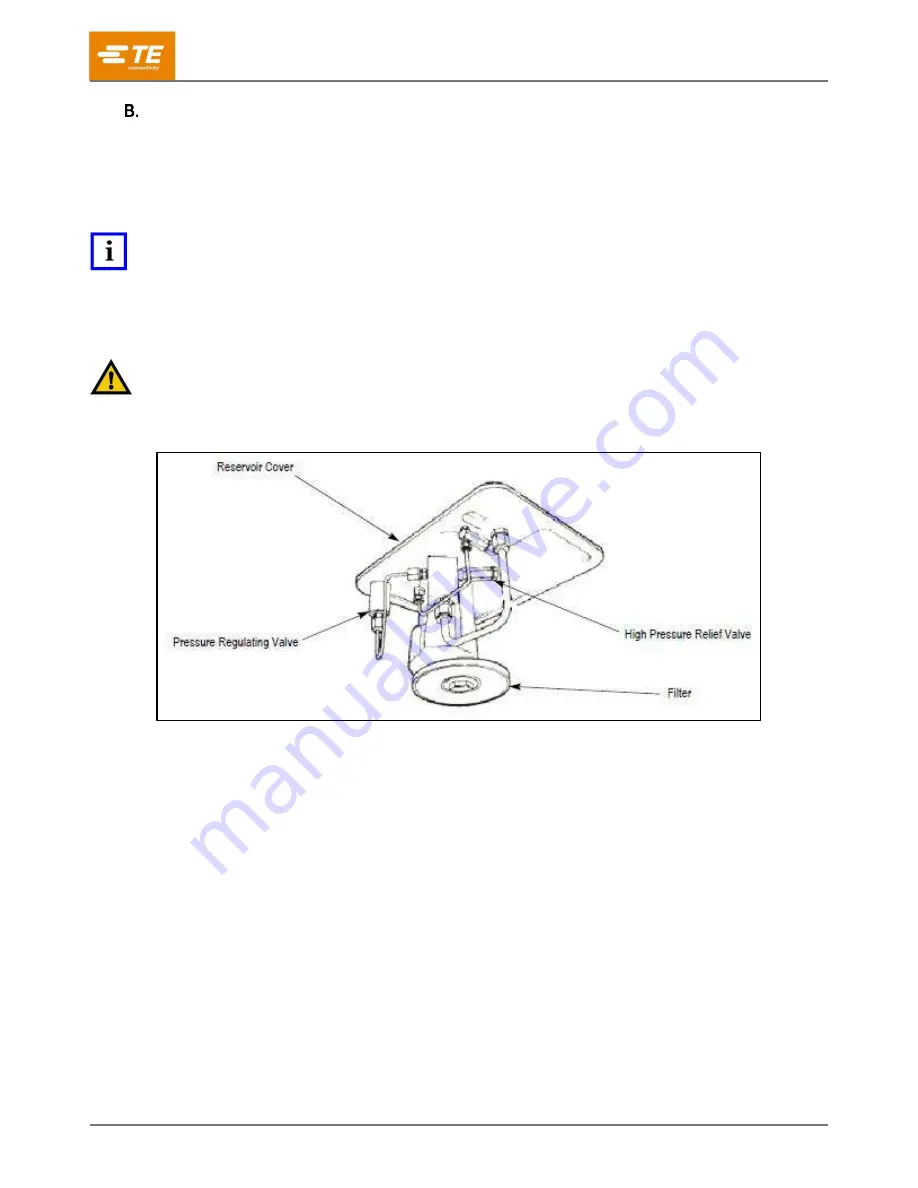

CAUTION

BE CAREFUL not to damage the filter or any of the valves when lifting the motor and pump assembly off of the hydraulic fluid

reservoir. Refer to Figure 8.

Figure 8: Motor and pump assembly

5. Clean the inside of the reservoir. Rinse the filter until it is clean.

6. Fill the reservoir with approved, high-grade hydraulic oil (refer to Table 12).

7. Place the pump and motor assembly (with the gasket) on the reservoir, then install and evenly

tighten the 10 screws.

8. Connect the pump to the power supply, and cycle the pump (fully extend and retract the cylinders)

several times, ending with the cylinders retracted.

6.3.

Bleeding Air from Hydraulic System

Air can accumulate in the system when the oil level becomes too low. The accumulation causes the cylinders

to respond in an unstable or slow manner. If this becomes evident, release the air from the system as follows:

1. Position the crimping heads so that the quick-disconnect coupler is facing UPWARD.

2. Depress the DUMP switch to release the pressure from the system. Make sure that the cylinder is fully

retracted. Then DISCONNECT the pump from the power supply.

3. Re-connect the pump to the power supply, then cycle the pump (fully extend and retract the cylinders)

several times, ending with the cylinders retracted.