408-4087

2 of 5

Rev C

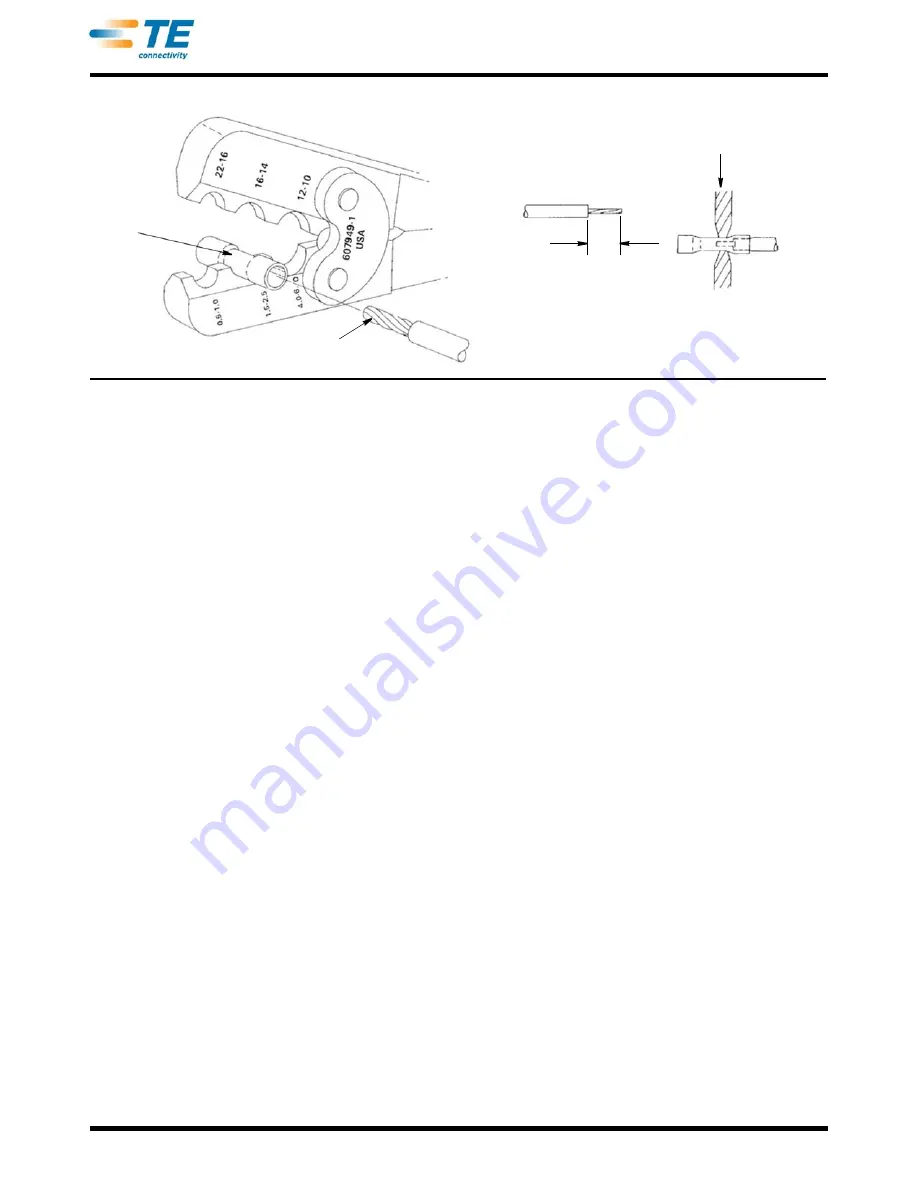

Figure 2

4.2. Periodic Inspection

Hand tool should be immersed (handles partially

closed) in a reliable commercial degreasing

compound which does not attack paint or plastic

material, to remove accumulated dirt, grease, and

foreign matter. The tool should be re-lubricated after

cleaning. The tool may then be wiped clean with a

soft, lint-free cloth. Do NOT use hard or abrasive

objects that could damage the tool. Ensure that the

tool conforms to the information in Figure 6.

A. Lubrication

Lubricate all pins, pivot points, and bearing surfaces

with SAE

†

20 motor oil as follows:

•

Tools used in daily production - lubricate daily

•

Tools used daily (occasionally) - lubricate weekly

•

Tools used weekly - lubricate monthly

Wipe excess oil from tool, particularly from crimping

area. Oil transferred from the crimping area onto

certain terminations may affect the electrical

characteristics of an application.

B. Visual Inspection

1. Close tool handles until ratchet releases and then

allow them to open freely. If they do not open

quickly and fully, the tool is defective and must be

replaced. See Section 6, REPLACEMENT.

2. Inspect jaws for worn, cracked, or broken areas.

If damage is evident, the tool must be replaced. See

Section 6, REPLACEMENT.

C. Gaging the Crimping Chamber

This inspection requires the use of plug gages

conforming to the dimensions in Figure 3.

TE Connectivity does not manufacture or market these

gages. To gage the crimping chamber, proceed as

follows:

1. Remove traces of oil or dirt from crimping

chamber and plug gages.

2. Close the tool handles until it is evident that the

jaws have bottomed, then HOLD in this position. Do

NOT force the jaws beyond initial contact.

3. Align the GO element with the crimping chamber.

Push element straight into the crimping chamber

without using force. The GO element must pass

completely through. Refer to Figure 3.

4. Now align the NO-GO element and try to insert it

straight into the same crimping chamber. The NO-

GO element may start entry but must not pass

completely through as shown in Figure 3.

If the crimping chamber conforms to the gage

inspection, it is considered dimensionally correct and

should be lubricated with a THIN coat of any good

SAE 20 motor oil. If not, the tool must be replaced.

See Section 6, REPLACEMENT.

D. Ratchet Inspection

Obtain a .025 mm [.001 in.] shim that is suitable for

checking the clearance between the bottoming

surfaces of the crimping jaws. (See Figure 3).

Proceed as follows:

1. Select a contact and wire (maximum size) for the

tool (see Figure 3).

Conductor

Crimp

Area

Stripped Wire

Crimping

Jaws

L = 7.14 [.281] 22-16-14 AWG

L= 9.53 [.375] 12-10 AWG

Splice

L

†

SAE is a trademark.