114-13233

Rev B

9

of 13

3.13.

PC Board Connectors

A.

PC Board Material and Thickness

PC board material may be glass epoxy (FR-4, G-10), or other TE Engineering approved substrates.

The pc board contact can be installed on various thickness of pc board. Board thickness may vary

depending upon the application, however, contact tail length through the pc board becomes important for

wave soldering operations. A recommended minimum of 1.27 mm [.050 in.] of the contact solder tail

should protrude through the pc board.

Contact the Product Information Center or the Tooling Assistance Center number listed at the bottom

of page 1 for suitability pc board materials or thicknesses.

B.

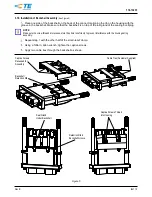

PC Board Layout

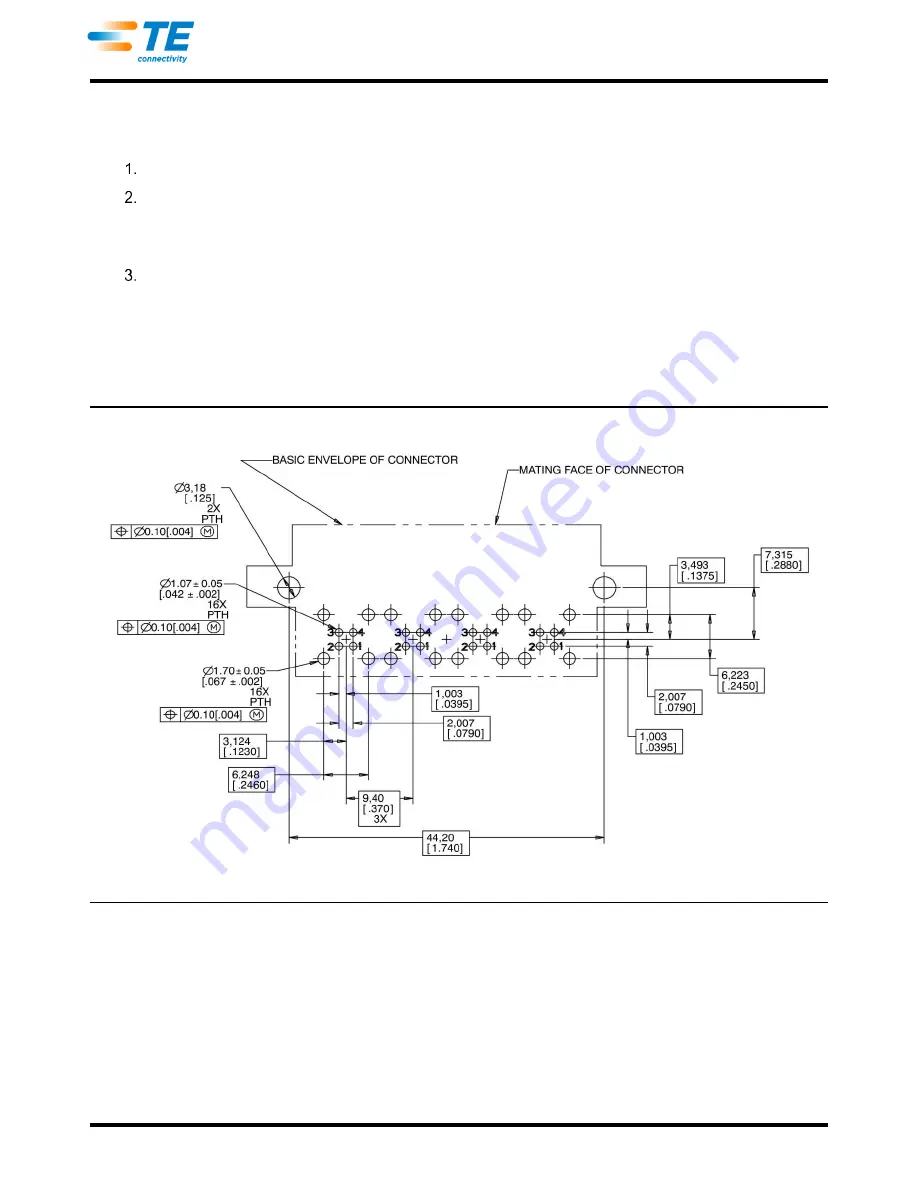

The contact holes in the pc board must be located as shown to ensure proper placement and

performance of the connector. Design the pc board using the dimensions provided in Figure 9. The layout

shows the top (component) side of the board.

Figure 9

C.

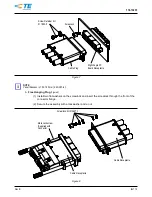

Contact Holes

The contact holes in the pc board must be precisely located to ensure proper placement and optimum

performance of the connector, and must be prepared to the requirements provided in Figure 10.

3.14.

Connector Spacing

Care must be taken to avoid interference between adjacent connectors and/or other components. There is no

required spacing between connectors, however spacing may be dependent on variable hardware used and the

clearance required for mating connectors.