AFTER SALES SUPPORT

1300 922 271

MODEL NUMBER: BT-RH1500, 08/11

8

(C) on the rotary switch (3) whilst at the same time

turning the rotary switch (3) into position B (see Fig. 9).

Important.

Please note that it is not possible to operate the hammer drill

with the hammer stop and rotation stop facilities both active

at the same time.

Important.

Only low pressure is required for hammer drilling. Excessive

pressure will exert an unnecessary force on the motor. Check

the drill bits at regular intervals. Sharpen or replace blunt drill

bits.

7. Replacing the power cable

If the power cable for this equipment is damaged, it must

be replaced by the manufacturer or its aftersales service or

similarly trained personnel to avoid danger.

8. Cleaning, maintenance and

ordering of spare parts

Always pull out the mains power plug before starting

any cleaning work.

8.1 Cleaning

•

Keep all safety devices, air vents and the motor housing

free of dirt and dust as far as possible.

•

Wipe the equipment with a clean cloth or blow it with

compressed air at low pressure.

•

We recommend that you clean the device immediately

each time you have finished using it.

•

Clean the equipment regularly with a moist cloth and

some soft soap. Do not use cleaning agents or solvents;

these could attack the plastic parts of the equipment.

Ensure that no water can seep into the device.

8.2 Carbon brushes

In case of excessive sparking, have the carbon brushes

checked only by a qualified electrician.

Important!

The carbon

brushes should not be replaced by anyone but a qualified

electrician.

8.3 Maintenance

There are no parts inside the equipment which require ad-

ditional maintenance.

8.4 Ordering spare parts

Please quote the following data when ordering replacement

parts:

•

Type of machine

•

Article number of the machine

•

Identification number of the machine

•

Replacement part number of the part required

TAURUS® is a trademark of ALDI Stores

ALDI Guarantee

Specially made for ALDI Stores to our stringent quality

specifications. If you are not entirely satisfied with this product,

please return it to your nearest ALDI store within 60 days from

the date of purchase for a full refund or replacement, or take

advantage of our after sales support by calling the supplier’s

Customer Service Hotline.

ALDI STORES

1 SARGENTS ROAD

MINCHINBURY NSW 2770

AUSTRALIA

www.aldi.com.au

08/2011

Art.Nr: 42.584.81_11011

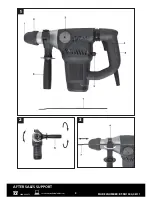

5.1 Additional handle (Fig. 2 – Item 6)

For safety reasons you must only use the hammer drill with

the additional handle.

The additional handle (6) enables you to achieve better

stability whilst using the hammer drill. The machine must not

be used without the additional handle (6) for safety reasons.

The additional handle (6) is secured to the hammer drill by a

clamp. Turning the handle anti-clockwise (looking from the

handle) will release the clamp. Turning the handle clockwise

will tighten the clamp. First release the additional handle

clamp. You can then swing the additional handle (6) into the

most comfortable working position for you. Now turn the

additional handle in the opposite direction again until the

additional handle is secure.

5.2 Depth stop (Fig. 3 – Item 7)

The depth stop (7) is held in place with the locking screw (a)

on the additional handle (6) by means of a clamp.

•

Undo the locking screw (a) and fit the depth stop (7).

•

Set the depth stop (7) to the same level as the drill bit.

•

Pull the depth stop (7) back by the required drilling

depth.

•

Retighten the locking screw (a).

•

Now drill the hole until the depth stop (7) touches the

workpiece.

5.3. Tool insertion (Fig. 4)

•

Clean the tool before insertion and apply a thin coating

of drill bit grease to the shaft of the tool.

•

Pull back and hold the locking sleeve (2).

•

Insert the dust-free tool into the tool mounting as far

as it will go whilst turning it. The tool will lock itself.

•

Check that it is properly secure by pulling the tool.

5.4 Tool removal (Fig. 5)

Pull back and hold the locking sleeve (2) and remove the

tool.

5.5 Dust collection device (Fig. 6)

Slide the dust collection device (a) over the drill bit before

carrying out any hammer drilling vertically above your head.

6. Starting up

Important. To prevent all danger, the machine must only be

held using the two handles (6/8).

Otherwise there may be a risk of suffering an electric shock

if you drill into cables.

6.1 Switching on and off (Fig. 1)

To switch on: Press the control switch (4).

To switch off: Release the control switch (4).

6.2 Hammer stop facility (Fig. 7)

The hammer drill has a hammer stop facility for

gentle initial drilling.

•

Turn the rotary switch for the hammer stop facility (5)

to position (B) to switch off the hammer facility.

•

To switch on the hammer facility again the rotary

switch for the hammer stop facility (5) must be turned

back to position (A).

6.3 Rotation stop facility (Fig. 8 / 9)

The rotation function of the hammer drill can be

switched off for chiseling jobs.

•

To do this, press the button (C) on the rotary switch

(3) whilst at the same time turning the rotary switch

(3) into position A (see Fig. 8).

•

To switch on the rotation facility again, press button