©Copyright Task Force Tips LLC 2011-2018

LIG-010 May 29, 2018 Rev05

7

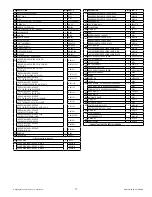

4.0 FLOW CHARACTERISTICS

4.1 FIXED FLOW

A fixed flow G-Force nozzle has one fixed discharge orifice and a flush setting. A fixed flow G-Force is flush able with the selector

ring. Figure 4.2A-D shows flow and pressure graphs for the G-Force Fixed nozzles.

4.2 SELECTABLE FLOW

A selectable G-Force nozzle has several fixed discharge orifices and a flush setting. A particular orifice is selected by rotating the

selector ring. Figure 4.2A-D shows flow and pressure graphs for the G-Force Selectable nozzles.

0

20

40

60

80

100

120

140

0

20

40

60

80

100

120

140

160

180

200

220

Flow (gpm)

Pressure

(psi

)

0

1

2

3

4

5

6

7

8

9

0

100

200

300

400

500

600

700

800

Flow (LPM)

Pressure

(BAR

)

A

B

C

D

E

FLUSH

A

B

C

D

E

E

150 GPM @ 100 PSI

570 l/min @ 700 kPa (7 bar)

FIXED GALLONAGE

SELECTABLE GALLONAGE

G**A**

G**C**

60

30

95

150

125

GPM @ 100 PSI

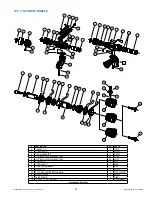

Figure 4.2A

1.5” G-Force 100 psi Fixed and Selectable Nozzles

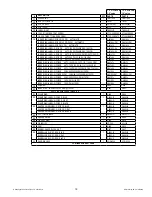

3.2 SPECIFICATIONS

3.2.1 MECHANICAL

1.5”

1.0”

1.0”

HIGH PRESSURE

Maximum operating pressure (with valve shut off) 370 psi / 25.5 bar 370 psi / 25.5 bar

580 psi / 40.0 bar

Operating temperature range of fluid

33 to 120º F / 1 to 50º C

Storage temperature range

-40 to 150º F / -40 to 65º C

Materials used

Aluminum 6000 series hard anodized MIL8625 class 3 type

2, stainless steel 300 series, nylon 6-6, nitrile rubber

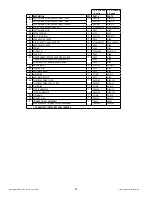

3.3 NOZZLE COUPLINGS

Many inlet couplings such as NH (National Hose) is standard or NPSH (National Pipe Straight Hose) and other threads can be

specified at time of order.

CAUTION

Nozzle must be mated to a hose line with matched threads. Mismatched or damaged threads may

cause nozzle to leak or uncouple under pressure and could cause injury.

CAUTION

Dissimilar metals coupled together can cause galvanic corrosion that can result in the inability

to unscrew the threads or complete loss of thread engagement over time. Per NFPA 1962, if

dissimilar metals are left coupled together an anti-corrosive lubricant should be applied to the

threads. Also the coupling should be disconnected and inspected at least quarterly.

3.4 USE WITH SALTWATER

Use with saltwater is permissible provided nozzle is thoroughly cleaned with fresh water after each use. The service life of the nozzle

may be shortened due to the effects of corrosion and is not covered under warranty.