16

•

Screw Feed Version:

Raise the blade out of the cut by pulling up on the

depth control lock and slowly turning the hand wheel

clockwise. Raise the blade (2E) high enough out of

the cut to clear the pavement when maneuvering the

saw.

•

E-Z Tilt Version:

Raise the blade out of the cut by loosening the lock

handle and pulling back on the handle bar. Raise the

blade (2E) high enough out of the cut to clear the

pavement when maneuvering the saw when tightening

the lock handle.

•

Turn off the Water Valve (1A).

•

Turn the Engine Throttle to the IDLE position.

•

STOP the engine by turning the Engine Switch (1D) to

the OFF position.

•

Follow all of the instructions outlined above.

•

Open the Water Valve (1A) FULL open. Check the

water to verify full flow, then adjust for proper amount

of water on the blade BEFORE you lower the Blade.

•

Set the handle bar height to a comfortable position.

•

Raise the Blade (2E) as high as possible so that the

Blade (2E) will not strike pavement when maneuvering.

WARNINGS!!!

DO

turn the “ON/OFF” switch to the “OFF” position prior

to connecting the machine to the power source.

DO

make sure electric powered machines are plugged

into a properly grounded circuit.

DO

make sure power cords are the proper size and in

good condition.

DO

follow all electrical codes in your area.

DO

use correct voltage and proper extension cords.

Never carry tool by cord or yank it to disconnect it

from receptacle. Keep cord away from heat, oil and

sharp edges.

DO

disconnect tools from power source when not in use,

before servicing and when changing accessories.

DO

carefully maintain and clean for better and safer

performance. Follow instructions for changing

accessories. Inspect tool cords periodically and, if

damaged, have repaired by authorized service

facility.

DO NOT

lay power cords in or near the water.

DO NOT

leave this machine unattended with the motor

running.

DO NOT

replace the motor with any motor that does not have

a special grounding connection.

2. Electric motors of any make can burn out when the voltage

supply falls 10% below the voltage rating of the motor. Use

proper heavy duty fuses in the circuit. Use No. 8 wire for

extension cord lengths up to 100 ft. long. Under-sized

wires can cause motor burnout. Check the voltage at the

motor when the saw is cutting.

3. Single phase concrete saw motors are equipped with

manual reset overloads. When the overload trips, turn the

switch to the

OFF

position. Allow the motor to cool 5 to

10 minutes, then push the reset button. A click indicates

reset.

Test for adequate water supply [2-1/2 to 5 gal/

min (10 to 20 lit./min)]. Low water flow will cause

damage to diamond blades.

If water supply is interrupted, stop cutting

immediately.

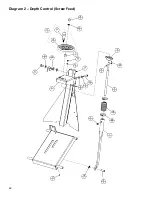

Screw Feed Version:

•

Lower the blade into the cut by pulling up on the Depth

Control Lock (1E) and slowly turning the Hand Wheel

COUNTER-CLOCKWISE. When the desired depth

of cut is reached, push Depth Control Lock down to

lock it in the hand wheel.

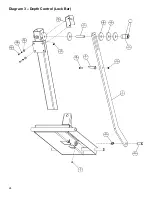

E-Z Tilt Version:

•

The blade on this saw may be lowered into the

concrete by loosening the lock handle and pushing

forward on the handle bar. The weight of the saw will

assist when lowering the blade. The blade is held at

the desired depth by tightening the lock handle on the

lock bar.

•

During cutting, DO NOT exert excessive side pres-

sure on the Handle Bars to attempt to “STEER” the

saw. Use only enough pressure to follow the previ-

ously marked line.

•

If the saw should stall for any reason, (close the air

valve on the air models and turn the power switch off

on the electric models) raise the blade completely out

of the cut before starting your power source again!

•

When lowering the Blade (2E) into a partially made

cut, the blade must be perfectly aligned within the cut

before starting to saw again. DO NOT FORCE the

Blade (2E) into the material by lowering the Blade too

fast, or by propelling the saw too fast.

7

To Maneuver the Saw

8

To Start Sawing

9

Stopping the Saw

Summary of Contents for MC18

Page 3: ...3 NOTE NOTA...

Page 8: ...8 NOTE NOTA...

Page 19: ...19 NOTE NOTA...

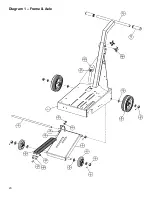

Page 20: ...20 Diagram 1 Frame Axle...

Page 22: ...22 Diagram 2 Depth Control Screw Feed...

Page 24: ...24 Diagram 3 Depth Control Lock Bar...

Page 26: ...26 Diagram 4 Pointer Belt Guard...

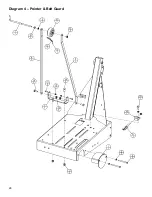

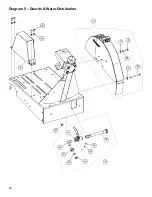

Page 28: ...28 Diagram 5 Guards Water Distribution...

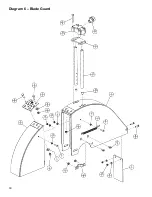

Page 30: ...30 Diagram 6 Blade Guard...

Page 32: ...32 Diagram 7 Engine Bladeshaft...

Page 34: ...34 Diagram 8 Electric Motor...

Page 36: ...36 Diagram 9 Air Motor...

Page 39: ...39 NOTE NOTA...