OPERATING MANUAL

PLASMA CUTTING

GB

Inglese

GB

4.2 Cutting start-up

Read the standards CEI 26/9 – CENELEC HD 407 and CEI 26.11 – CENELEC HD

433 carefully before using the equipment, and make sure the cable insulation is

fully intact. Make sure the trigger has not been pressed.

Turn the machine on using the switch B. The warning lamp D will light and thermal

lamp E will blink for 5 sec. to indicate that the machine is on.

Press the torch trigger briefly to open the flow of compressed air ; for first start the

-

re isn’t pilot arc but only air flow to clean the air hose from . Since the arc is

not lit, air leaves the torch for 20-25 sec.

Connect the grounding clamp to the workpiece. The cutting circuit must not be

deliberately placed in direct or indirect contact with the protective wire except in the

workpiece. If the workpiece is deliberately grounded using the protective conductor,

the connection must be as direct as possible and use a wire of at least the same

size as the cutting current return wire, and connected to the workpiece at the same

point as the return wire clamp or a second grounding clamp placed in the immedia-

te vicinity. Every precaution must be taken

to

avoid stray currents. Use the knob C to

select the cutting current.

Make sure that the grounding clamp and workpiece have a good electrical contact,

especially with painted, oxidized or insulated sheet metal.

Do not connect the grounding clamp to the part of the material that is to be remo-

ved. Press the torch trigger to strike the pilot arc.

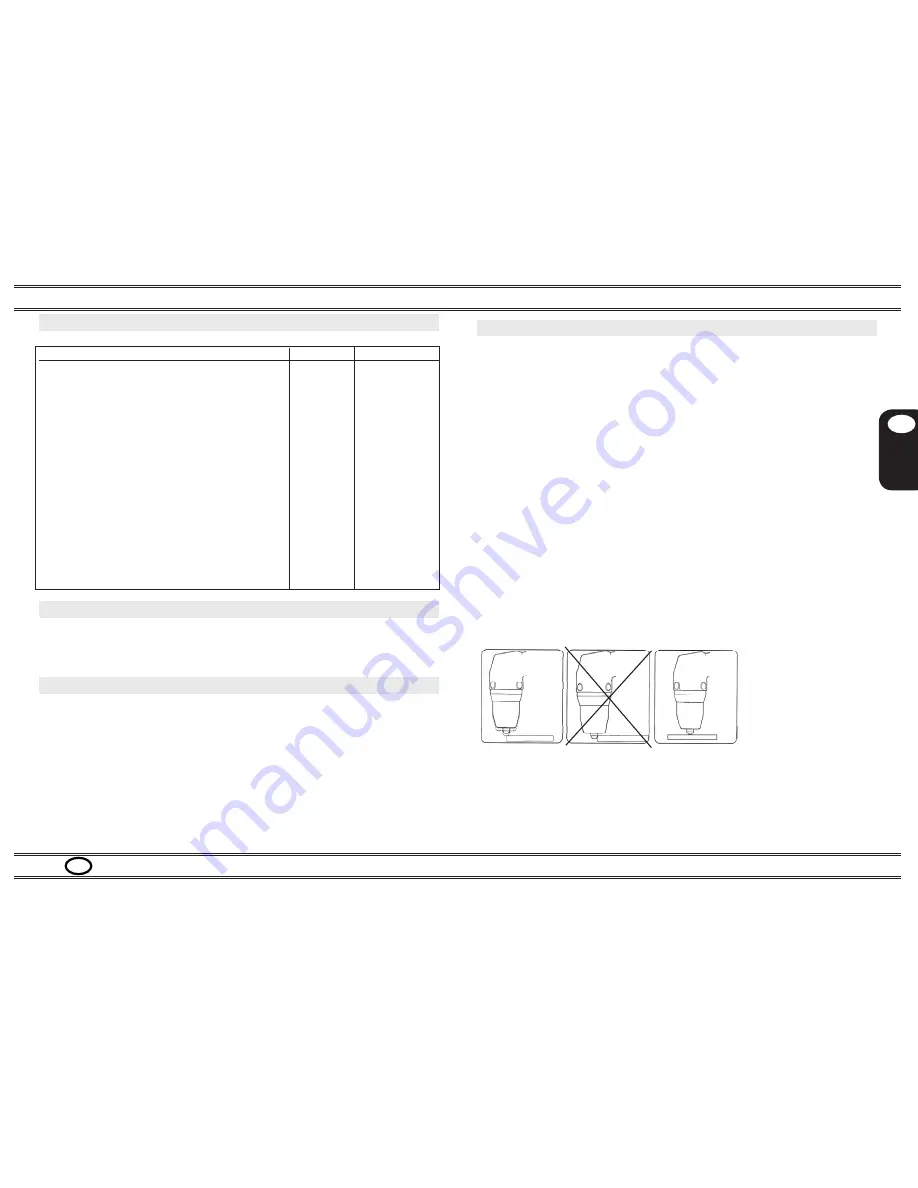

Begin cutting as shown in fig. 5a, avoid starting as shown in fig. 5b. Further during

cutting operation the torch have to keep in contact with workpiece in order to avoid

torch overheating

(Picture 5c).

Picture 5a Picture 5b Picture 5c

3.4 Technical specifications table (table 2)

Technical data

Site Cut 10

Main supply (-15%/+15%)

VAC

1ph x 230V

Frequency

Hz

50/60

Main power (60%)

KVA

2,6

Open

circut

voltage V0

V

250

Current range I2

A

13-25

Arc pilo

t

current I2

A

11-13

Cutting current I2 (X%)

A

25

I2 (60%)

A

25

I2 (100%)

A

20

Recommended cutting capacity

mm

6

Maximum cutting capacity

mm

8

Severence cutting capacity

mm

10

Gas flow

bar

Air compressor.

Insulation class

F

Protection degree

IP

21S

Dimensions

mm

425x210x415

Weight

Kg

19,0

4. Start-up and use

The machine must be installed by qualified personnel. All connections must be

made in compliance with current safety standards and full observance of safety

regulations.

4.1 Main supply connection

Connect the power cord A: the yellow-green cable wire must be connected to an

efficient grounding socket on the system. The remaining wires must be connected

to the power supply line by means of a switch placed as close as possible to the

cutting area, to allow it to be shut off quickly in case of emergency.

The capacity of the cut-out switch or fuses installed in series with the switch must

be equal to the current I1 absorbed by the machine.

The absorbed current I1 may be determined by reading the technical specifications

shown on the machine under the available supply voltage U1 .

Any extension cords must be sized appropriately for the absorbed current I1.

PAGE 5

pump