www.tanakapowerequipment.com

4

Owner’s Manual

PF-2600

Drain all fuel from fuel tank and pull fuel filter line from tank. Pull filter

element out of holder assembly. Replace filter if it appears to be

discolored or hardened from use. The filter has a white, felt-like

appearance when new.

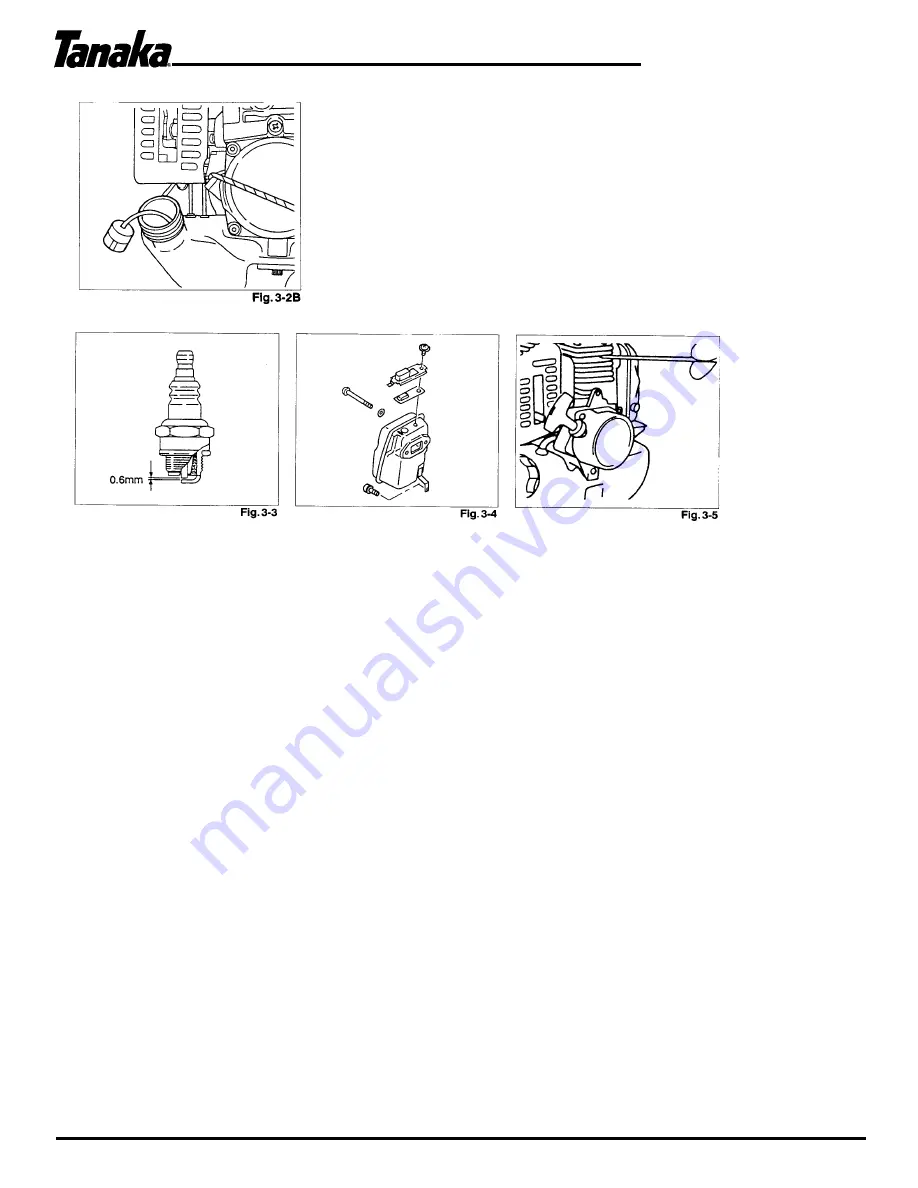

Spark plug (Fig. 3-3)

The spark plug condition is influenced by:

• An incorrect carburetor setting.

• Wrong fuel mixture (too much oil in the gasoline)

• A dirty air filter.

• Difficult running conditions (such as cold weather).

These factors cause deposits on the spark plug electrode, which may result in malfunction and starting difficulties. If the engine

is low on power, difficult to start or runs poorly at idling speed, always check the spark plug first. If the spark plug is dirty, clean

it and check the electrode gap. Readjust if necessary. The correct gap is 0.6 mm (.024”). The spark plug should be replaced

after about 100 operation hours or earlier if the electrode is badly eroded.

NOTE!

In some areas, local law requires using a resistor spark plug to suppress ignition signals. If this machine was originally equipped

with resistor spark plug, use the same type of spark plug for replacement.

Muffler (Fig. 3-4)

Remove the muffler and clean excess carbon from the exhaust port or muffler inlet every 100 hours of operation.

If you find corrosion on the muffler, replace it.

Cylinder (Engine cooling) (Fig. 3-5)

The engine is air cooled, and air must circulate freely around engine and over cooling fins on cylinder head to prevent

overheating.

Every 100 Operating hours, or once a year (more often if conditions require), clean fins and external surfaces of engine of

dust, dirt and oil deposits which can contribute to improper cooling.

NOTE!

Do not operate engine with engine shroud or muffler guard removed as this will cause overheating and engine damage.

Fuel Filter (Fig. 3-2B)