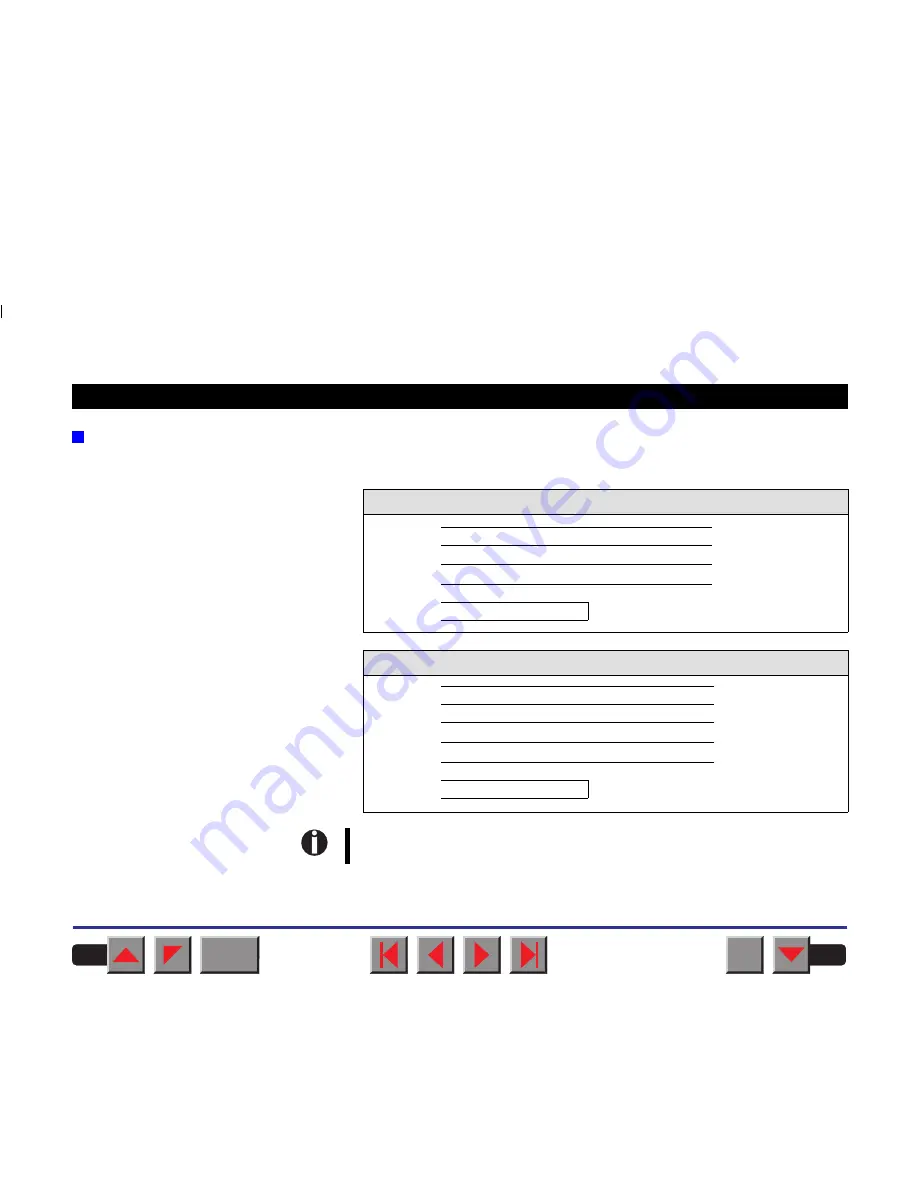

Interface cable

(serial interface)

The cables used must be shielded. The cable shield must be connected

to the connector shield on both ends.

PC/AT (9-pin)

Printer (9-pin)

RxD

TxD

CTS

SG

DSR

DTR

2

3

8

5

6

4

3

2

4

5

TxD

RxD

DTR/RDY

SG

PC/AT (25-pin)

Printer (9-pin)

FG

TxD

RxD

CTS

SG

DSR

DTR

1

2

3

5

7

6

20

2

3

4

5

FG

RxD

TxD

DTR/RDY

SG

It depends on the menu setting whether DTR or RDY is active at

pin 4.

BACK

QUIT

?

Reference manual

Interfaces

161