Tally Dascom DL-830

User Guide V1.0

50

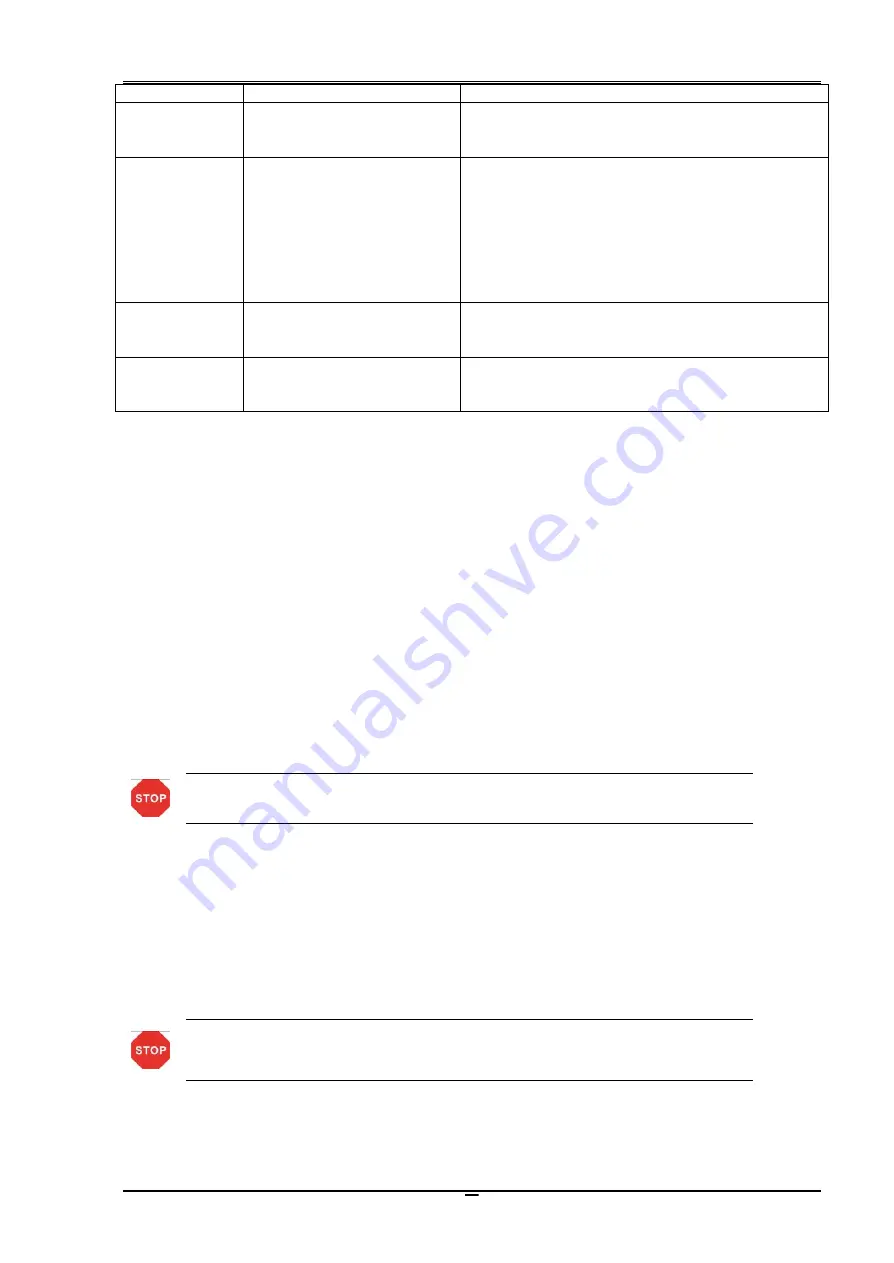

Faults

Probable Causes

Recommended Solutions

Choose proper media sensor sensitivity. If the

problem

persists,

change

the

sensor

sensitivity level in System Setup.

Winkled ribbon

Improper ribbon tension

Left/right tension of the

ribbon not balanced

Incorrect darkness

Improper media and ink

ribbon

Turn the Ribbon Winding Knob to adjust the

tension.

Turn the Ribbon Balance Dial.

Choose the proper density in the menu or

driver settings.

Use genuine and correct type of supplies.

(

Consult the re-seller for supplies

.

)

Slipping ribbon

(dirts

accumulate)

Improper ribbon tension

Turn the Ribbon Winding Knob to adjust the

tension.

Jammed ribbon

Incorrect ribbon winding

Reversed ribbon

Reload the ribbon correctly

Install the ribbon in the correct winding

direction.

5.2 Restore factory default settings

Sometimes restoring factory default settings helps to resolve the problems. There are three

ways to do it:

When turn on the power, hold the ►► key until the power LED flashes 4 times and the

buzzer beeps 4 times.

Use the Configuration Tool to restore factory defaults.

Use control panel to restore factory defaults.

5.3 Clear jammed media

Caution

:

Beware of high temperature near the print head.

Turn off the power. Open the top cover. Unlock and lift the print head.

Remove the media attached to the ribbon. Remove the ribbon. Use a cotton swab, soaked

with alcohol to clean up the print head.

Reload the media.

Reload the ribbon. Turn the winding knob to get the affected portion of ribbon out of the way.

5.4 Clean the print head

Let the head cool down before cleaning.

Avoid damage to the head with finger nails or solid objects.

Turn off the power. Open the top cover and unload the ribbon. Clean the head with a cotton

swab soaked with alcohol (alcohol, methanol, or isopropyl alcohol).