User Guide

Options and accessories

Specifications

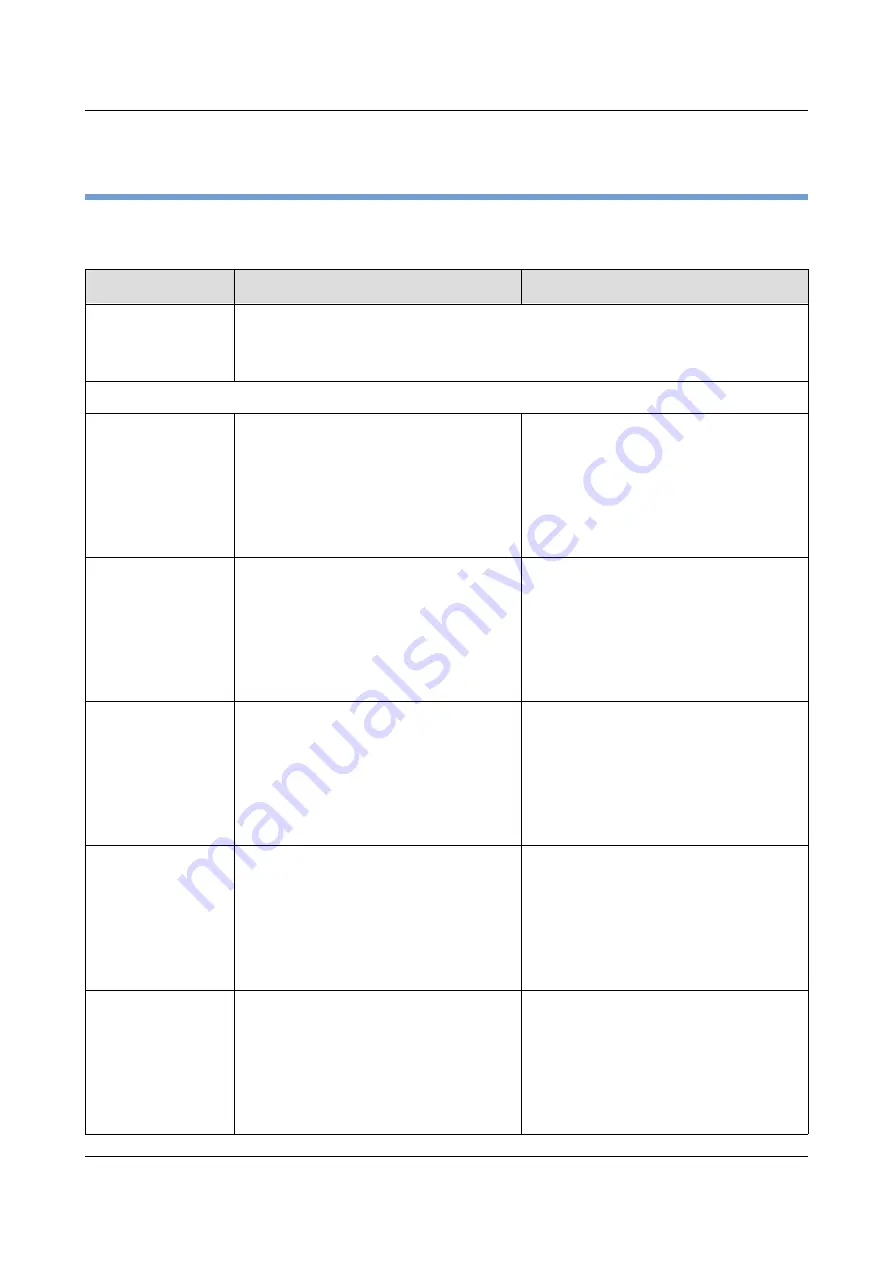

Printer specifications

2810

2820

Printer system

Serial impact matrix printer

Printhead with 24 needles, 0.25 mm

∅ 0.25 mm

bidirectional printing

Print speed and character matrices

HSQ (High Speed

Quality)

800 cps | 12 x 10, 10.0 CPI 90 x 100

960 cps | 12 x 08, 12.0 CPI 90 x 96

1000 cps | 08 x 08, 15.0 CPI *) 90 x 120

1000 cps | 12 x 08, 15.0 CPI 90 x 120

1143 cps | 12 x 06+1, 17.1 CPI 90 x 120

1333 cps | 12 x 05+1, 20.0 CPI 90 x 120

1000cps | 12 x 10, 10.0 CPI 90 x 100

1200 cps | 12 x 08, 12.0 CPI 90 x 96

1250 cps | 08 x 08, 15.0 CPI *) 90 x 120

1250 cps | 12 x 08, 15.0 CPI 90 x 120

1428 cps | 12 x 06+1, 17.1 CPI 90 x 120

1667 cps | 12 x 05+1, 20.0 CPI 90 x 120

Draft (Data Print

Quality)

667 cps | 12 x 12, 10.0 CPI 90 x 120

800 cps | 12 x 10, 12.0 CPI 90 x 120

1000 cps | 08 x 08, 15.0 CPI *) 90 x 120

1000 cps | 12 x 08, 15.0 CPI 90 x 120

571 cps | 12 x 12+2, 17.1 CPI 90 x 240

667 cps | 12 x 10+2, 20.0 CPI 90 x 240

833 cps | 12 x 12, 10.0 CPI 90 x 120

1000 cps | 12 x 10, 12.0 CPI 90 x 120

1250 cps | 08 x 08, 15.0 CPI *) 90 x 120

1250 cps | 12 x 08, 15.0 CPI 90 x 120

714 cps | 12 x 12+2, 17.1 CPI 90 x 240

833 cps | 12 x 10+2, 20.0 CPI 90 x 240

Copy Draft (Copy

Print Quality)

333 cps | 24 x 12, 10.0 CPI 180 x 120

400 cps | 24 x 10, 12.0 CPI 180 x 120

500 cps | 16 x 08, 15.0 CPI *) 180 x 120

500 cps | 24 x 08, 15.0 CPI 180 x 120

285 cps | 24 x 12+2, 17.1 CPI 180 x 240

333 cps | 24 x 12+2, 20.0 CPI 180 x 240

417 cps | 24 x 12, 10.0 CPI 180 x 120

500 cps | 24 x 10, 12.0 CPI 180 x 120

625 cps | 16 x 08, 15.0 CPI *) 180 x 120

625 cps | 24 x 08, 15.0 CPI 180 x 120

356 cps | 24 x 12+2, 17.1 CPI 180 x 240

417 cps | 24 x 12+2, 20.0 CPI 180 x 240

NLQ (Near Letter

Quality)

222 cps | 24 x 18, 10.0 CPI 180 x 180

267 cps | 24 x 15, 12.0 CPI 180 x 180

333 cps | 16 x 12, 15.0 CPI *) 180 x 180

167 cps | 24 x 18+6, 15.0 CPI 180 x 360

190 cps | 24 x 18+3, 17.1 CPI 180 x 360

222 cps | 24 x 15+3, 20.0 CPI 180 x 360

278 cps | 24 x 18, 10.0 CPI 180 x 180

333 cps | 24 x 15, 12.0 CPI 180 x 180

417 cps | 16 x 12, 15.0 CPI *) 180 x 180

208 cps | 24 x 18+6, 15.0 CPI 180 x 360

238 cps | 24 x 18+3, 17.1 CPI 180 x 360

278 cps | 24 x 15+3, 20.0 CPI 180 x 360

LQ (Letter Quality)

111 cps | 24 x 36, 10.0 CPI 180 x 360

133 cps | 24 x 30, 12.0 CPI 180 x 360

167 cps | 16 x 24, 15.0 CPI *) 180 x 360

167 cps | 24 x 18+6, 15.0 CPI 180 x 360

190 cps | 24 x 18+3, 17.1 CPI 180 x 360

222 cps | 24 x 15+3, 20.0 CPI 180 x 360

139 cps | 24 x 36, 10.0 CPI 180 x 360

167 cps | 24 x 30, 12.0 CPI 180 x 360

208 cps | 16 x 24, 15.0 CPI *) 180 x 360

208 cps | 24 x 18+6, 15.0 CPI 180 x 360

238 cps | 24 x 18+3, 17.1 CPI 180 x 360

278 cps | 24 x 15+3, 20.0 CPI 180 x 360

123

Summary of Contents for 2810

Page 1: ...User guide Matrix printer 2810 2820 ...

Page 17: ...User Guide Options and accessories Printer at a glance 9 ...

Page 18: ...Options and accessories User Guide Printer in tractor mode 10 ...

Page 52: ...Options and accessories User Guide 46 ...

Page 62: ...User Guide Options and accessories 59 ...

Page 83: ...User Guide Options and accessories 81 ...

Page 90: ...Options and accessories User Guide Menu settings example 88 ...

Page 96: ...User Guide Options and accessories 95 ...

Page 108: ...User Guide Options and accessories 107 ...

Page 129: ...User Guide Options and accessories MTPL standard character set 129 ...

Page 130: ...User Guide Options and accessories MTPL international substitution characters 131 ...

Page 131: ...Options and accessories User Guide OCR A character set 132 ...

Page 132: ...User Guide Options and accessories OCR B character set 133 ...