6. Remove the old seal seat and cup from the seal face

plate. Lubricate the new cup with soapy water and

install new parts in the face plate recess. Replace the

face plate to its original position. Carefully tap the face

plate evenly into the recess in the motor housing.

7. Clean the impeller shaft before installing the new seal.

8. Lubricate the impeller shaft with soapy water. Do not

install new seal on a dry impeller shaft or damage to

seal may result.

9. Slide the new carbon seal and spring assembly onto

the shaft until it contacts the seal seat.

10. While holding the rotor in place as in Step 3, thread the

impeller onto the shaft in a counter-clockwise direction

until it stops. Check to make sure the pump will rotate.

If the impeller will not spin freely, contact Taco Technical

Support at 1-401-942-8000.

11. Remove old body gasket and replace with new gasket

provided in seal kit. Press gasket into seal face plate,

then attach motor to casing. Use caution not to pinch

body gasket or leaks may result.

12. Attach the pump casing to the motor housing and

secure with the four body bolts. Be sure flow arrow on

casing is pointing in proper direction. Tighten the four

bolts evenly in a criss-cross pattern to 70 in-lb of

torque. There should be a small, even gap between the

casing and the motor mounting bracket.

13. Re-install circulator into system using new flange

gaskets, if required.

14. Reconnect electrical wiring. Do not open electrical sup-

ply to pump until “System Start-Up” steps are complete.

SYSTEM START-UP:

1. Prior to pump start-up, closed heating and cooling sys-

tems should be thoroughly cleaned, flushed and drained.

2. Open isolation valves and re-fill system with clean water.

Check for any leaks.

3. Vent all air from system at an air vent located at the

high point in the system.

4. Start circulator to check for proper operation.

PERIODIC INSPECTION, MAINTENANCE:

Taco 2400 Series Hi-Capacity circulators are designed to

provide years of trouble-free service. However, periodic

inspection and routine maintenance is recommended for all

hydronic systems and mechanical equipment. If any evi-

dence of leakage or damage is present, take preventive

steps to repair or replace the circulator immediately.

CAUTION: Do not start the pump until the sys-

tem has been completely filled and vented.

Running the pump dry may damage the

mechanical seal and void warranty.

CAUTION: Do not allow screwdriver to make

contact with motor windings or insulation.

Permanent damage to motor may result.

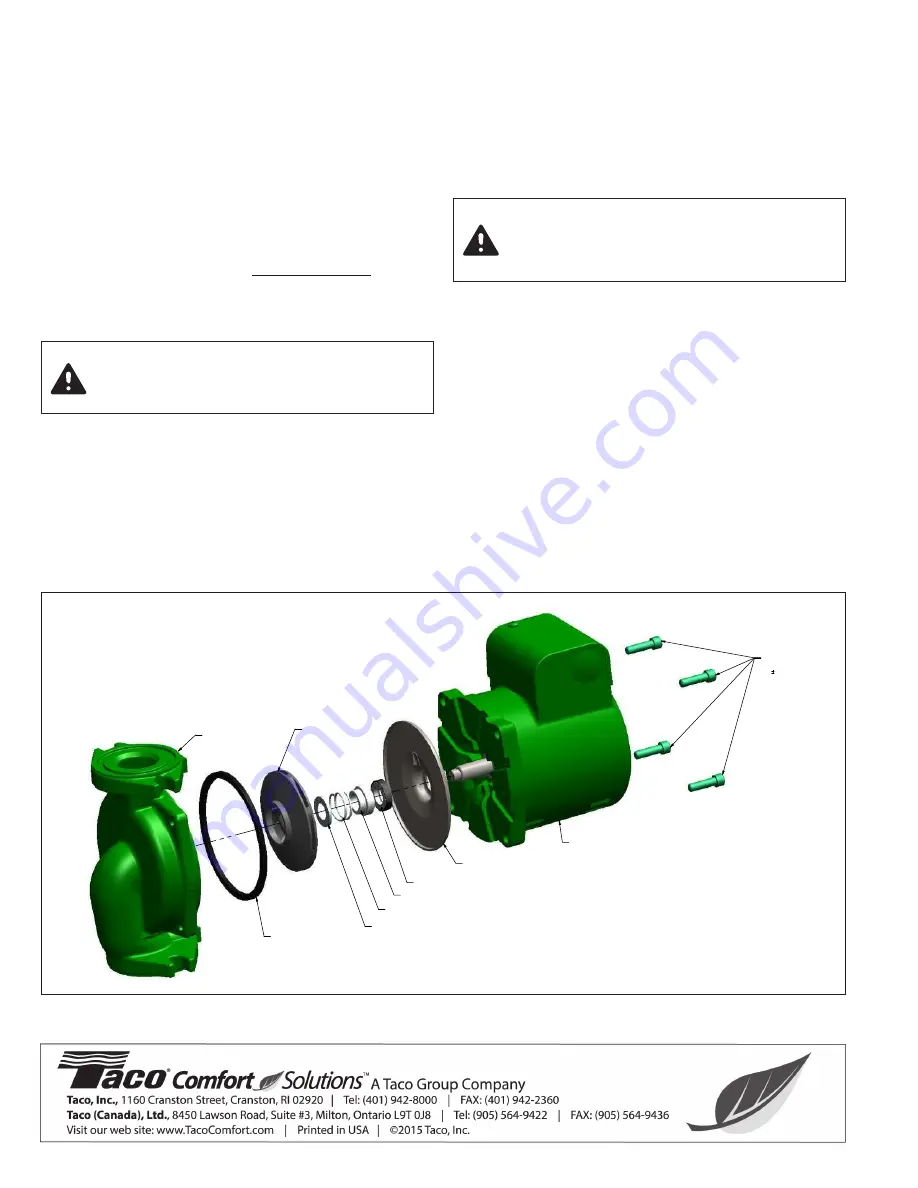

Fig. 1: Exploded View of Pump

SEAL SPRING

BODY GASKET

SEAL RETAINER

CASING

MOTOR ASSEMBLY

FACE PLATE

ROTATING SEAL

IMPELLER

BODY BOLTS (4)

TORQUE TO

65 15 IN-LBS

STATIONARY SEAL

2400 (3P MODELS)

TACO, INC.

, 1160 Cranston Street, Cranston, RI 02920 Telephone: (401) 942-8000 FAX: (401) 942-2360.

TACO (Canadá), Ltd.

, 8450 Lawson Road, Unit #3, Milton, Ontario L9T 0J8. Telephone: 905/564-9422. FAX: 905/564-9436.

Visit our web site at:

http://www.taco-hvac.com

Printed in USA

Copyright 20150

TACO, Inc.