TAC-H

2

S/H

2

O/O

2

Pg. 16

TEXAS ANALYTICAL CONTROLS

4418 Bluebonnet Drive | Stafford, TX 77477 | (281) 240-4160 |

www.tac-controls.com

4 Controls and Their Operation

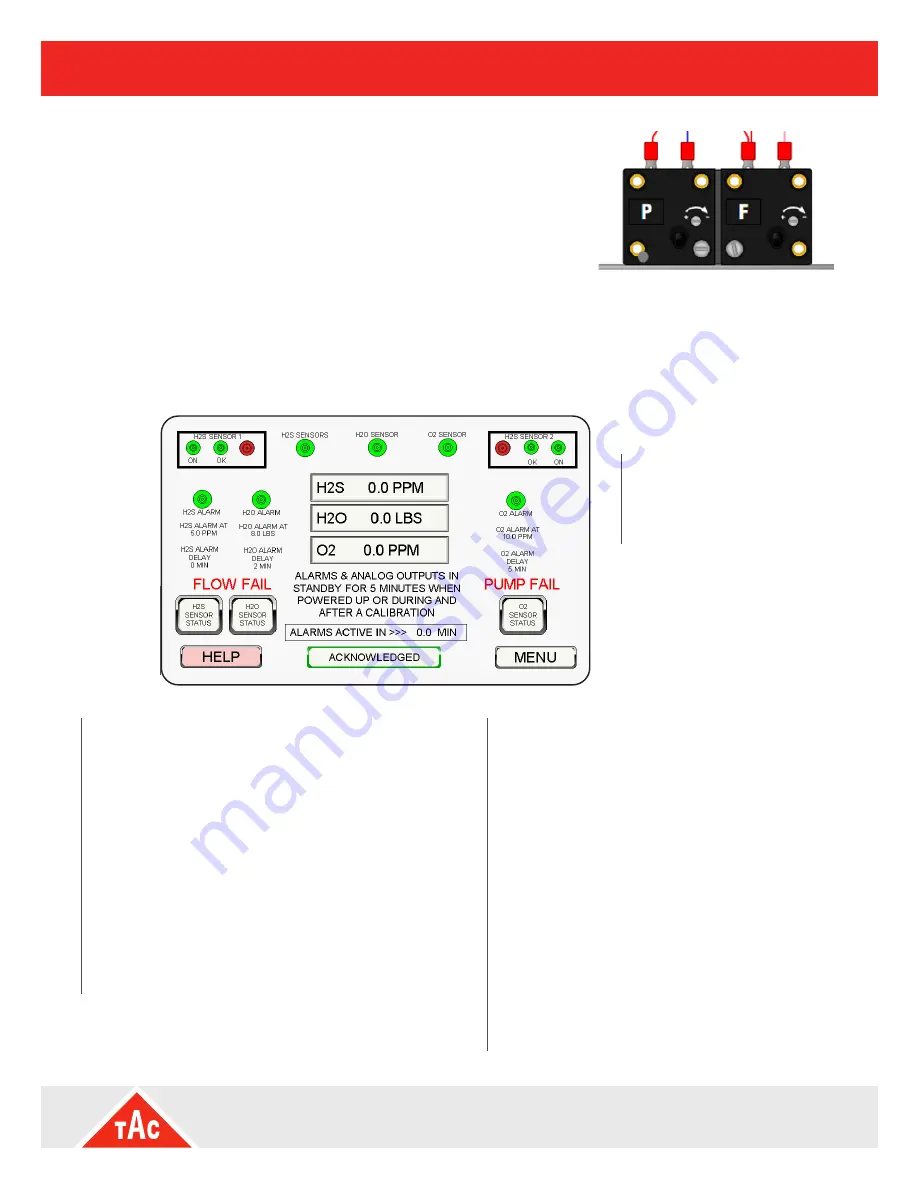

4.6.2 Pump & Flow Fail Alarms

There are two pressure sensors in each analyzer; one for the

internal pump and one if the flow is obstructed to the analyzer.

The internal pump that clears the H

2

S sensors between cycles

typically lasts 3-5 years. If it fails, the main screen will flash

“PUMP FAIL.” If the sample flow is obstructed, the analyzer will

stop functioning and the main screen will flash “FLOW FAIL.”

If either fail alarm re-occurs, and you suspect a

false failure

,

the pump or flow fail switch can be adjusted. If the switch has been adjusted and the pump or flow fail

warning returns, then the pump or flow fail warnings can be disabled until the switch can be replaced.

During a pump or flow fail, the main screen displays the following:

Pump/Flow Fail Assembly – 12v or 24v

To Clear Flow Fail

1 Ensure that the regulators and flow meter(s) are

working properly.

2 Check that the sample line for obstructions and

clear them.

3 Press the ACKNOWLEDGED button on the main

screen to clear alarm.

To Clear Pump Fail

1 Touch the pump to verify that it is still vibrating

and, therefore, working properly.

2 Press the ACKNOWLEDGED button on the main

screen to clear alarm.

To Adjust the Pump or Flow Fail Sensor

1 Using a flat head screwdriver turn the

potentiometer clockwise a ½ turn.

2 Press the ACKNOWLEDGED button on the

main screen to clear alarm.

3 Wait approximately 2 minutes to make sure

the flow or pump fail doesn’t return. Repeat the

process if necessary.

4 If the trim pot screw is bottomed out then the

switch will need to be replaced.

To Turn Off Fail Warnings

1 From the alarm setting menu, press the PUMP or

FLOW FAIL button to display the settings screen.

2 Press the UP/DOWN ARROWS to toggle between

“on” and “off” and press ENTER to save.

Tip:

The following

instructions are also

available by pressing

the HELP button on

the menu screen.

FAIL

FAIL