5

I56-3102-003

7/8/2019

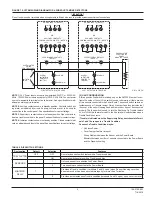

FIGURE 7. SYSTEM WIRING DIAGRAM FOR 4-WIRE DUCT SMOKE DETECTORS

CAUTION

Do not loop wire under terminals when wiring detectors. Break wire runs to provide system supervision of connections.

24VAC/DC

9

10

AUXILIARY CONTACTS

FOR FAN SHUTDOWN, ETC. (NOTE 2)

16

6

17

8

18

7

N.O.

C.

N.C.

N.O.

C.

N.C.

16

6

17

8

18

7

N.O.

C.

N.C.

N.O.

C.

N.C.

SUPERVISORY CONTACTS

(NOTE 3)

24V

9

10

AUXILIARY CONTACTS

FOR FAN SHUTDOWN, ETC. (NOTE 2)

SUPERVISORY CONTACTS

(NOTE 3)

SUP C.

SUP N.O.

SUP N.O.

SUP C.

5

4

ALARM

INITIATION

CONTACTS

(NOTE 4)

5

4

ALARM

INITIATION

CONTACTS

(NOTE 4)

INITIATION

LOOP

ULC/FM LISTED

4-WIRE

CONTROL PANEL

+

120

VAC

120

VAC

OR

OR

AUX A

AUX B

AUX A

AUX B

ALARM C.

ALARM C.

ALARM N.O.

ALARM N.O.

14

14

3

3

FIRST DETECTOR IN THE LOOP

POWER INPUTS (NOTE 1)

POWER INPUTS (NOTE 1)

LAST DETECTOR IN THE LOOP

EOL RESISTOR

SPECIFIED BY

PANEL

MANUFACTURER

NOTE 1:

24V Power Inputs accept a non-polarized 24VDC or 24VAC 50-

60Hz. 120VAC Power Inputs accept only 120VAC 50-60Hz. Connect power

source to appropriate terminals of each detector. See specifications for ad-

ditional power supply information.

NOTE 2:

Auxiliary contacts shown in standby position. Contacts switch dur-

ing alarm as indicated by arrows. Auxiliary contacts are not to be used for

connection to the control panel. See specifications for contact ratings.

NOTE 3:

Supervisory contacts shown in standby position. Open contacts in-

dicate a trouble condition to the panel. See specifications for contact ratings.

NOTE 4:

Initiation contacts shown in standby position. Closed contacts indi-

cate an activated condition to the panel. See specifications for contact ratings.

H0558-02CDN

Designation

Default

Selection

Features

TRBL SHUTDN

OFF

OFF

Aux relay does not switch states with a Trouble condition

ON

Aux relay switches states with a Trouble condition

SENSORS

1

1

Only one sensor is connected the Power Board

2

Two sensors are connected to the Power Board

MIN TMPR

DELAY

7

7

Provides a Trouble condition ( terminals 3 and 14 open) when Sensor Housing cover has

been removed or has been secured improperly for more than 7 minutes

0

Provides an instantaneous Trouble condition(terminals 3 and 14 open) upon cover removal

TABLE 2. DIP SWITCH SETTINGS

[9] UNIT CONFIGURATION

A three position Dip Switch is included only on the D4P120A in order to con-

figure the setup of the unit. One switch is used to determine it there are one

or two sensors connected to the Power Board. The second switch selects an

instantaneous or 7-minute tamper Delay. A tamper Condition indicates that

the cover of the sesor Housing has been removed or has not been secured

properly. The third switch is used to turn the Shutdown On Trouble feature

on or off. With this feature turned On, the Aux relay will switch states when a

Trouble Condition occurs.

*Trouble is indicated when the Supervisory Relay, switches state-Termi-

nals 3 and 14 are open in a Trouble Condition

Causes of a Trouble Condition may be:

• Unit loses Power

• Cover Tamper Feature times out

• Wiring Problems between the Sensor and the Power Board

• Mismatch between number of sensors connected to the Power Board

and the Dipswitch setting