D200-09-00

3

I56-1986-000

C0169-00

C0170-00

Cleaning

It is recommended that the detector be removed from

its mounting base to facilitate cleaning. The detector is

cleaned as follows:

NOTE:

Before removing the detector, notify the proper

authorities that the smoke detector system is

undergoing maintenance and will be temporarily

out of service. Disable the zone or system under-

going maintenance to prevent unwanted alarms.

1. Remove the detector cover by prying away the four

side tabs with a small-bladed screwdriver, and then

pulling the cover from the base.

2. Vacuum the screen carefully without removing it. If

further cleaning is required continue with Step 3, oth-

erwise skip to Step 7.

3. Remove the screen/chamber cover assembly by pull-

ing it straight out (see Figure 4).

4. Clean the chamber by vacuuming or blowing out dust

and particles.

5. Replace the sensing chamber cover, aligning the

arrow on the top with arrow on the printed circuit

board.

6. To replace the screen, place it over the chamber

assembly, turning it until it snaps into place.

7. Replace the cover using the LEDs to align the cover

and then gently pushing it until it locks into place.

8. Reinstall the detector.

9. Test the detector as described in TESTING.

10. Reconnect disabled circuits.

11. Notify the proper authorities that the system is back

on line.

C0146-00

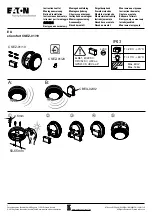

Figure 2. Rotary decade address switches:

Figure 3. Test magnet position:

TENS

ONES

9

8

7

6

5

4

3

2

1 0

9

8

7

6

5

4

3

2

1 0

D

N

T

N

I

A P

T

O

O

LED STATUS

INDICATORS

TES

T

MAGNET

PAINTED

SURFACE

PAINTED

SURFACE

TEST

MAGNET

MAGNET TEST

MARKER

Figure 4. Sensor assembly:

SENSING

CHAMBER

SCREEN

ASSEMBLY

SENSOR

COVER

COVER REMOVAL

TABS