D200-63-00

2

I56-931-02

Mounting

Each 1112/24B and 1112/24BA detector is supplied with a

mounting bracket that permits the detector to be mounted:

1. To a single gang box, or

2. Directly to a 3

1

/

2

-inch or 4-inch octagonal box, or

3. To a 4 inch square electrical box by using a plaster ring.

Wiring Installation Guidelines

All wiring must be installed in compliance with the Na-

tional Electrical Code, applicable local codes, and any spe-

cial requirements of the local authority having jurisdiction.

Proper wire gauges should be used. The conductors used to

connect smoke detectors to control panels and accessory

devices should be color-coded to reduce the likelihood of

wiring errors. Improper connections can prevent a system

from responding properly in the event of a fire.

The screw terminal block accepts 14 – 22 gauge wire. For

best system performance, all wiring should be installed in

separate grounded conduit. Do not mix fire system wiring

in the same conduit as any other electrical wiring. Twisted

pair may be used to provide additional protection against

electrical interference.

A78-2336-01

P

W

R

OPTIONAL CLASS A WIRING

EOL RESISTOR

SPECIFIED BY

PANEL

MANUFACTURER

EOL POWER

SUPERVISION

RELAY (SHOWN

ENERGIZED)

A77-716 12/24V

POWER

TO

DETECTORS

UL LISTED

CONTROL

PANEL

INITIATING

LOOP

+

–

+

–

P

W

R

+

+

–

–

N.O.

C

+

+

–

–

N.O.

C

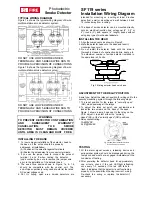

Figure 2. 1112/24B and 1112/24BA detector

mounting bracket:

ALIGNMENT ARROWS

TAMPER RESISTANT TAB

(CUT OFF SMALL TAB TO

ACTIVATE TAMPER-RESIST

FEATURE)

Figure 1. Surface mounting 1112/24B and 1112/24BA

detectors on 3

1

/

2

-inch and 4-inch octagonal box:

A78-2563-00

,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,

,,,,,,,,,,,,,,,,,,,,,,,,,

A78-2333-02

Figure 3. Wiring diagram for the 1112/24B(A) detector:

Smoke detectors and alarm system control panels have

specifications for allowable loop resistance. Consult the

control panel specifications for the total loop resistance al-

lowed for the control panel being used before wiring the

detector loops.

Wire connections are made by stripping about

1

/

4

inch of

insulation from the end of the feed wire, inserting the wire

into the appropriate terminal, and tightening the screw to

secure the wire in place.

Tamper-Resist Feature

This detector includes a tamper-resist feature that prevents

its removal from the bracket without the use of a tool. To

make the detector tamper-resistant, remove the smaller tab

by breaking it at the scribed line on the tamper resistant tab

on the detector mounting bracket (see Figure 2), then in-

stall the detector. To remove the detector from the bracket

once it has been made tamper resistant, use a small screw-

driver to depress the tamper-resistant tab, located in the

slot on the mounting bracket (see Figure 4), and rotate the

detector counterclockwise.