OPERATION

Intended use:

This log splitter is intended and designed to only split wood. NEVER use for any

other purposes. Doing so can cause injury or VOID THE WARRANTY.

ASSEMBLY INSTRUCTIONS

This log splitter has been assembled at the factory. Refer to the drawings and part lists should it

become necessary to disassemble the unit for repair or replacement of parts. Inspect all components

for damage.

IMPORTANT:

This unit is shipped without hydraulic oil, after cycling the splitter wedge several

times to purge the air, check the oil reservoir and bring to a safe level.

WARNING:

Exercise extreme caution, as parts are very heavy. Sufficient persons or mechanical

handling equipment should be used.

•General Assembly: Remove top, sides and ends of crate. Cut all retaining straps and remove the

lag bolt that secures the kickstand to the pallet. Attach splitter to skid steer and lift off of the

pallet.

•Check both the horizontal and vertical positions for any “kinks” in the hoses. Note: Always make

sure beam is locked securely into place.

See

OPERATING POSITIONS

for Horizontal to Vertical Splitting

START UP

OPERATION

•Set up the log splitter in a clear, level area.

•Place a log on the beam, against the foot plate. Make sure the log is securely on the foot plate

and up against the beam.

•Depress the valve lever so that the cylinder will drive the wedge into the log. Extend the

cylinder until the log splits or to the end of its stroke. If the log has not completely split after the

cylinder has reached the end of its extension, retract the cylinder. NOTE: Leaving the valve in

the “actuate” position at the end of the stroke may damage the pump.

OPERATING POSITIONS

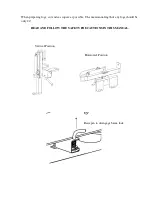

Changing Splitting Positions

The Splitter has 2 operating positions: Horizontal to Vertical positioning. With ample height to

allow kickstand to clear ground, rotate the splitter assembly to position the pivot tube to a

horizontal position. Lift the pin from below the beam to disengage. Rotate beam into the vertical

position and engage the pin to lock the beam in place.

CAUTION When rotating the beam from Vertical to horizontal, be sure that the hydraulic hose

does not get pinched.

WARNING: THE LOG SPLITTER BEAM IS HEAVY AND CAN PINCH HANDS/FINGERS IF

CARE IS NOT TAKEN.