Introduction

Technical Handbook

019722-101 Rev. 05

8

SC-350/360

>>>

3.4 Positional References

Unless stated the contrary, positions and directions such as left, right,

upper, lower, clockwise and counterclockwise are given with respect

to the machine when viewed from the front.

3.5 Modes of Operation

Refer to the

User’s guides

for information.

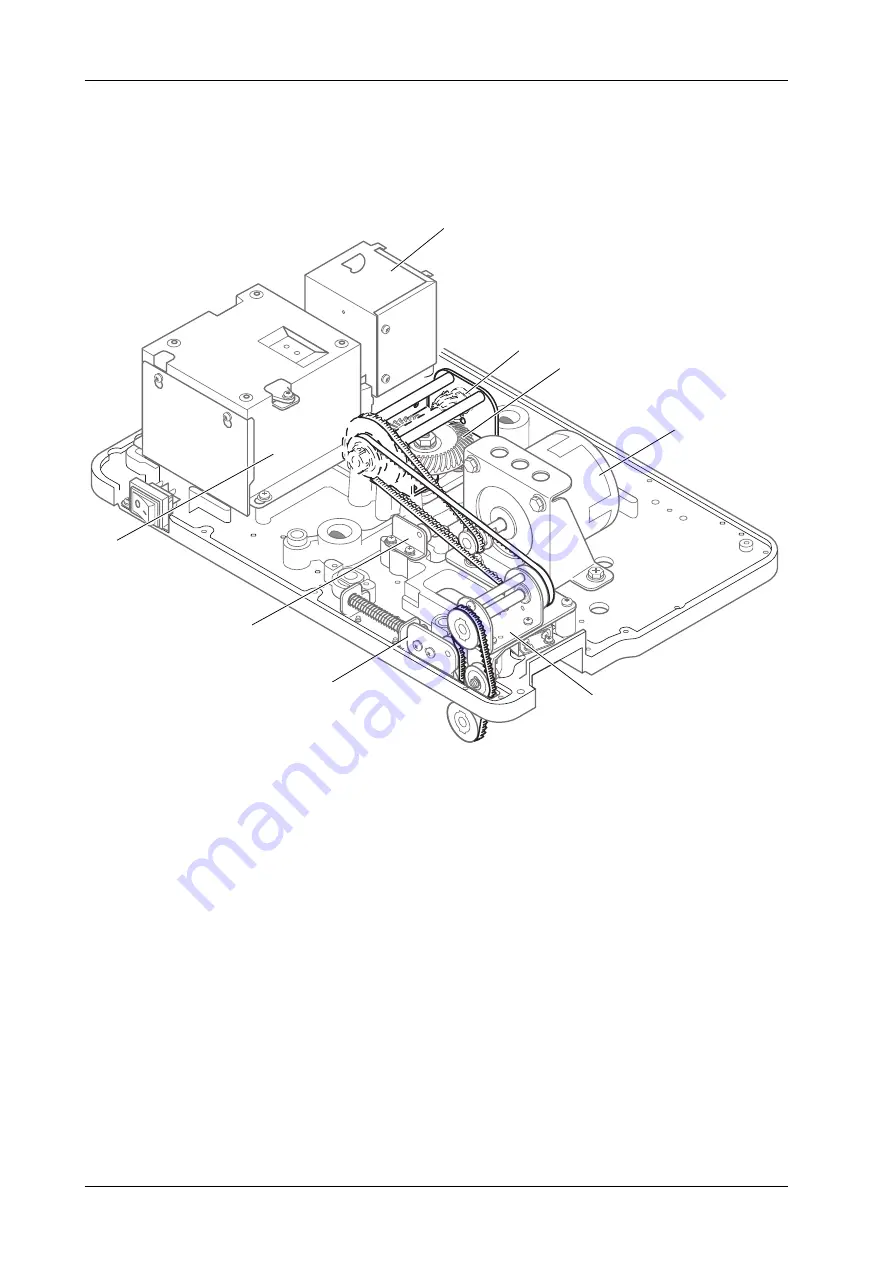

Machine turned upside down

9 Serial Interface & RD/AUX box

10 Pulley stand - Coin disc drive

11 Gear - Coin disc drive

Shaft and Bearing

12 Main motor

13 Pulley stand - Feeding

14 Belt stretcher

15 Support roller

16 Power supply box

9

10

11

12

13

14

15

16