8

GENERAL SAFETY RULES

Your GASOLINE WATERPUMP has many features

that will make your job faster and easier. Safety,

performance and reliability have been given

for top priority designing of this tool, qualities

to make easier its maintain and its operation.

This water pump has many good characteristics

such as maximum power, low noise, low fuel

consumption, low pollution, compact structure,

and small size. It’s used for project drain and

irrigation.

WARNING: Read and understand all instruc-

tions. Failure to follow all indications listed be-

low, may result in electric shock, fire and/or seri-

ous personal injury. SAVE THESE INSTRUCTIONS.

SAFETY IN WORKING AREA

Keep your work area clean and well lit. Cluttered

benches and dark areas may cause accidents.

Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases or dust. Some power tools create

sparks which may provoke fire.

Keep away observers, children and visitors

while operating a power tool. Distractions can

cause you to lose control.

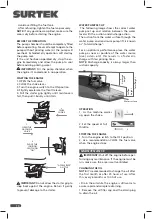

OHV / FOUR-STROKE ENGINES FEATURES:

• Four-stroke engines exhibit outstanding pow-

er and durability, operational noise is exception-

ally low. Also, exhaust is cleaner and there is less

smoke since there is no need to blend oil with

the gasoline.

• OHV engines consume approximately 30% less

fuel and 50% less oil than side valve engines.

SPECIFIC SAFETY RULES FOR

GASOLINE WATER PUMP

WARNING: Failure to follow these instruc-

tions and warnings may result in death, per-

sonal injury or property damage.

• For your safety, never pump flammable or cor-

rosive liquids such as gasoline or acid.

• Avoid pump corrosion, never pump sea water,

muddy water, chemical solutions, or caustic liq-

uids such as used oil, wine, or milk.

• Place the pump on a firm, level surface. If the

pump is tilted or overturned, fuel spillage may

be as result.

• To prevent fire hazards and to provide ad-

equate ventilation, keep the pump at least 1

meter (3 feet) away from buildings and other

equipment during operation.

• Do not place flammable objects close to the

pump. Check local laws and regulations before

operating.

• Learn how to stop the pump quickly, and un-

derstand the full operation of the controls.

• Do not allow anyone to operate the pump

without proper instructions. Do not allow chil-

dren to operate the pump. Keep children and

pets away from the area of operation.

IMPORTANT: Gasoline is extremely flam-

mable and is explosive under certain conditions

and circumstances.

• Do not smoke or allow flames near or where

the pump is refueled or anywhere gasoline is

stored.

Refuel in a well-ventilated area with the engine

stopped.

• Do not overfill the tank.

• Make sure that the filler cap is closed securely.

NOTE: Exhaust gas contains poisonous carbon

monoxide.

• Avoid inhalation of exhaust gasses.

• Never run the pump in a closed garage or con-

fined area.

• The muffler becomes very hot during opera-

tion and remains hot for a while after stopping

the engine.

• Be careful do not touch the muffler while it

is hot.

• Let the engine cool before storing the pump

indoors.

RISK OF CARBON MONOXIDE

Engine exhaust gases contain carbon monox-

ide, a poisonous, odorless, invisible gas that, if

inhaled in large proportions, can result in death

or serious personal injury. If you begin to feel

dizzy or weak while using the water pump, turn

it off and immediately go to a cool place; You

may suffer from carbon monoxide poisoning.

b) Good ventilation for cooling. Air circulation

and temperatures are important for air-cooled

units. Temperatures should not exceed 40 °C

(104 °F) of room temperature.

c) Fill the water pump with fuel in a well-lit area.

Avoid spilling fuel and never refill with fuel while

the water pump is running. Wait until the engine

cools for at least 2 minutes before refueling.

d) Do not refuel near flames, pilots or electrical

equipment that release sparks, such as power

tools, welders and grinders.

e) The engine must always have installed the

silencer and the air filter, which must be in good

condition at all times as they stop the fire in case

of an ignition in the engine.

f) Do not smoke near the water pump.

• Do not put anything in the ventilation slots,

even when the water pump is not in operation.

This can damage the water pump or cause per-

sonal injury.

Summary of Contents for MG544

Page 12: ...12 Notas Notes...

Page 13: ...13 Manual de usuario User s manual Notas Notes...