Stepping Systems

For a complete user manual, please visit www.automationdirect.com

Data Sheet: STP-MTRD-QSP, 1st Ed – 03/12/2018

Step 8:

Optionally, you can test motor operation by activating

switch 4 in the “SETUP” DIP switch bank to initiate a self

test. The self test continually rotates the motor forward

and backward 2 1/2 revolutions.

Additional Help and Support

• For product support, specifications, pricing and installation troubleshooting, a Hardware User

Manual can be downloaded from the Online Documentation area of the AutomationDirect web

site.

• For additional technical support and questions, call our Technical Support team

@ 1-800-633-0405 or 770-844-4200.

Step 7:

Optional settings in the “SETUP” DIP

switch bank–the default settings for these

switches are typically sufficient. See the User

Manual for details on these functions.

A.

[Switch 5] Step Pulse Noise Filter

B.

[Switch 6] Step Smoothing Filter

C.

[Switch 8] Step Pulse Type (Step/

Direction is default)

6

ON

6

OFF

SMOOTHING

8

CW PULSE/

CCW PULSE

STEP/

DIR

8

5

150

KHZ

5

2.0

MHZ

4

ON

4

OFF

SELF TEST

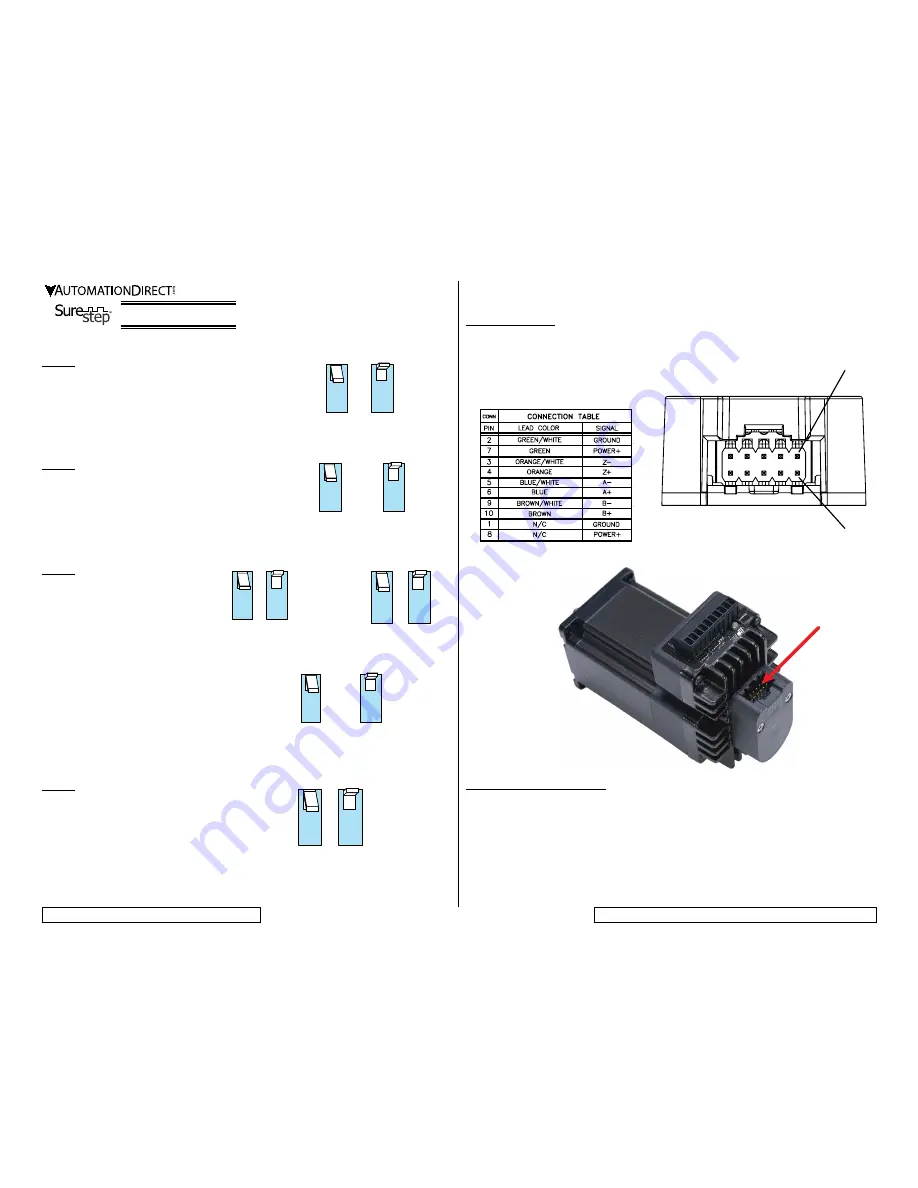

Optional Encoder:

An optional encoder is available pre-mounted on “E” models. The standard encoder is a 1000ppr, Differential

line driver encoder. See below for pinouts and wire colors for the replacement cable (STP-CBL-EAxx) and

included cable with the STP-MTRD.

For more information on the encoder, please

see the Sure Step User Manual. Replacement

encoder part number is STP-MTRA-ENC1.

PIN 1

PIN 2

Step 5:

In the “SETUP” DIP switch bank, set the motor’s idle

current using switch 3. This is the percentage of running

current that the motor will use when the shaft is not

rotating. Choose 90% for maximum holding torque or

50% to reduce motor heating.

Step 6:

In the “SETUP” DIP switch bank, select the load-to-

motor ratio category using switch 7. This is the ratio of the

effective load inertia to the motor’s own rotor inertia. For

high inertia loads choose 5-10X, and for low inertia loads

choose 0-4X. Setting the proper range for the load will

improve motor smoothness.

3

50%

3

90%

7

5-10X

7

0-4X

Encoder connection

N

ote

: P

iN

1

aNd

P

iN

2

are

iNterNally

coNNected

.

P

iN

7

aNd

P

iN

8

are

iNterNally

coNNected

iNside

the

eNcoder

.