32

SUPERIOR

®

E

n

g

li

s

h

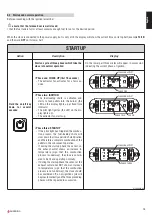

ROOM TEMPERATURE SENSOR

Sensor

Description

Display

Room sensor

Connected to the rear of the stove it constantly

monitors the temperature in the stove’s imme-

diate environs to ensure its operation in com-

plete safety.

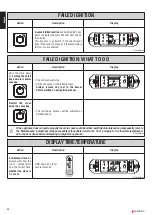

WHEN ACTIVATED

If the sensor detaches itself momentarily

and/or accidentally from its position, the prob-

lem does not require the immediate shutdown

of the stove, which will continue to function

normally at the chosen power level.

The problem will only be indicated if the tem-

perature display has been activated, in which

case a temperaure of 0ºC will be shown.

OK

SET

GRUPPO

PIAZZETTA

1

2

3

4

5

6

AL. F

SET

AL. C

OK

SET

GRUPPO

PIAZZETTA

1

2

3

4

5

6

AL. F

SET

AL. C

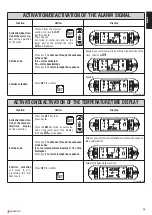

WHAT TO DO

Restore the sensor to its proper position;

If the temperature display has been activated

this will once again be shown.

OK

SET

GRUPPO

PIAZZETTA

1

2

3

4

5

6

AL. F

SET

AL. C

DT2040019-00

Example of display if temperature display is activated:

Example of display if time display is activated:

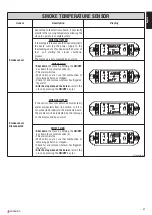

6.7

Opening the door

During operation the door must remain closed. It is to be opened only when the stove has shut down and cooled for the carrying out

of maintenance.

6.8

Removing the ash

The ash drawer must be emptied regularly. The ashes must never reach the level of the burner’s supporting arm.

The ashes must be put in a metal container with a sealable lid. Until the ashes are definitively extinguished, the container must be placed

on a non-combustible surface or on the ground and be kept well away from combustible material.

Ashes can conceal burning embers for long periods!!!