9

3 d)

Cont.

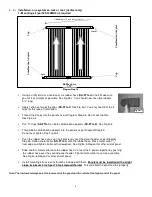

•

Push the rubber hose you cut in half previously over the panel header as per diagram Step 3d. Slide a metal

collar (

SK-FTG-L

) onto the rubber hose. Place metal collar

1

/

4

" from edge and tighten collar with screwdriver.

See Fig 3a-5. Repeat for other end of panel.

•

Slide another metal collar onto the rubber hose. Connect the 2 panels together by pushing the rubber hose

over the second panel header. Tighten metal collar to secure assembly. See Fig 3a-6. Repeat for other end of

panel.

•

Repeat previous 2 steps for other system.

•

You should now have two sets of connected panels. You need to use rubbers from the system kit

(

SK-FTG-K

) to connect the two set together as per Diagram Step3d.

•

Install mounting kits as per instructions included with them.

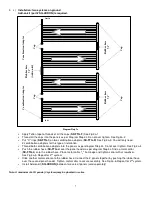

Panels must be installed with a slight

slope (minimum 2 inch per 10 feet) toward the inlet

. This will allow the panel to drain properly.

Note: The inlet must always be at the lower end of the panel and the outlet at the higher end of the panel.

Note: A maximum of 12 2ft panels (6 systems) may be plumbed in parallel

•

For high wind areas you can install the Nylon straps and Vinyl straps from System Kit.

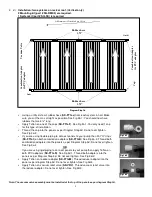

Mark a spot 6" to the top of the outlet. Mark spots 6" to the top of every second

rubber hose that are on the same side as the outlet. Mark a spot 6" to the top of the

vacuum relief valve. See Fig 3d-4. Place mounting base (

SK-RMK-BASE

) on these spots.

Drill pilot holes, apply silicone roof sealant and screw mounting base into roof. See Fig 3d-5.

Wrap a Nylon strap (

SK-RMK-ST-N32

) around the panel header (see Fig 3d-7) or

around rubber hose (see Fig 3d-6). Lay both ends of strap in the mounting base and

pull tight. See Fig 3d-8. Screw on mounting cap (

SK-RMK-CAP

). See Fig 3d-9.

Repeat process on the inlet side (bottom) of the panels but using the Vinyl straps

(

SK-RMK-ST-V32

) instead.

Fig 3d-6

Fig 3d-5

Fig 3d-4

Fig 3d-7

Fig 3d-8

Fig 3d-9