Section 2

ES-8 MOBILE APPLICATION MANUAL R00

11

INSTALLATION

2.1

LOCATION OF

COMPRESSOR

The ES-8 Series compressor package may be

placed on any level surface able to support its

weight. The unit is mounted on vibration mounts and

can be bolted to a fixed mounting surface to avoid

the possibility of externally applied forces or vibration

which would disturb the piping or wiring.

2.2

VENTILATION AND

COOLING

Select a location to permit sufficient unobstructed air

flow in and out of the compressor to keep the

operating temperature stable.

The minimum

distance that the machine should be from

surrounding walls and ceiling is what is needed

for service and three (3) feet (914mm) or more

from the compressor fluid cooler.

2.3

SERVICE AIR PIPING

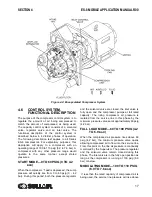

Service air piping should be installed as shown in

. A shut-off valve should be installed to

isolate the compressor from the service line. Also

notice that the service line should be equipped with

water legs and condensate drains throughout the

system.

WARNING

“The Plastic Pipe Institute recommends

against the use of thermoplastic pipe to

transport compressed air or other com-

pressed gases in exposed above ground

locations, e.g. in exposed plant piping.” (I)

Sullube 32 should not be used with PVC

piping systems. It may affect the bond at

cemented joints.Certain other plastic mate-

rials may also be affected.

(I) Plastic Pipe Institute, Recommendation

B, Adopted January 19, 1972.

Figure 2-1: Service Air Piping

Summary of Contents for 30XH

Page 10: ...NOTES 10 ...

Page 22: ...NOTES 22 ...

Page 33: ...NOTES 33 ...

Page 34: ...INLET CONTROL SEAL DRIVE GEAR AND PARTS 34 8 3 INLET CONTROL SEAL DRIVE GEAR AND PARTS ...

Page 36: ...MOTOR COUPLING FAN AND PARTS 36 8 4 MOTOR COUPLING FAN AND PARTS ...

Page 40: ...COMPRESSOR COOLER SYSTEM AND PARTS 40 8 6 COMPRESSOR COOLER SYSTEM AND PARTS ...

Page 42: ...PNEUMATIC CONTROL SYSTEM AND PARTS 42 8 7 PNEUMATIC CONTROL SYSTEM AND PARTS ...

Page 44: ...CONTROL STARTER MFV 44 8 8 CONTROL STARTER MFV ...

Page 46: ...DECAL GROUP 46 8 9 DECAL GROUP ...

Page 48: ...DECAL GROUP 48 8 9 DECAL GROUP CONTINUED ...

Page 50: ...WIRING DIAGRAM FULL VOLTAGE STANDARD 50 8 10 WIRING DIAGRAM FULL VOLTAGE STANDARD ...

Page 51: ...NOTES 51 ...