26

Section 6

VARIABLE SPEED DRIVE

Motor FLA -

The motor's rated full load amps at

nominal HP

(I)

Motor SF -

The motor's nameplate service factor

Motor V -

The motor's rated voltage

(I)

Motor Hz -

the motor's nameplate frequency

Motor RPM -

the motor's nameplate full-load speed

(I)

Some package designs employ motors connect-

ed for voltages lower (and FLA higher) than the

nominal voltage of the package, for improved per-

formance.

6.5 STARTUP OF NEW COMPRESSOR PACKAGE

1. Read and follow all safety warnings and cautions

in this manual.

2. At installation ensure:

• That the incoming power and ground wires

are properly connected to terminal blocks in

the electrical control box.

• Visually check all power and controls con-

nections to the drive to ensure that no dam-

age has occurred.

3. Check that moisture has not condensed inside

the variable speed drive.

4. Connect to the utility and switch the power on.

The Supervisor will establish communications

and report errors if correct conditions are not

found. If replacing a drive, communication faults

will be indicated for either improper communica-

tion wiring or improper application or communi-

cation software in the drive.

5. To check rotation, quickly press first the Start

then the Stop

key on the Supervisor. Com-

pressor rotation is factory set. If the fan rotates

incorrectly, disconnect power and simply inter-

change two of the fan motor leads at the fan

starter.

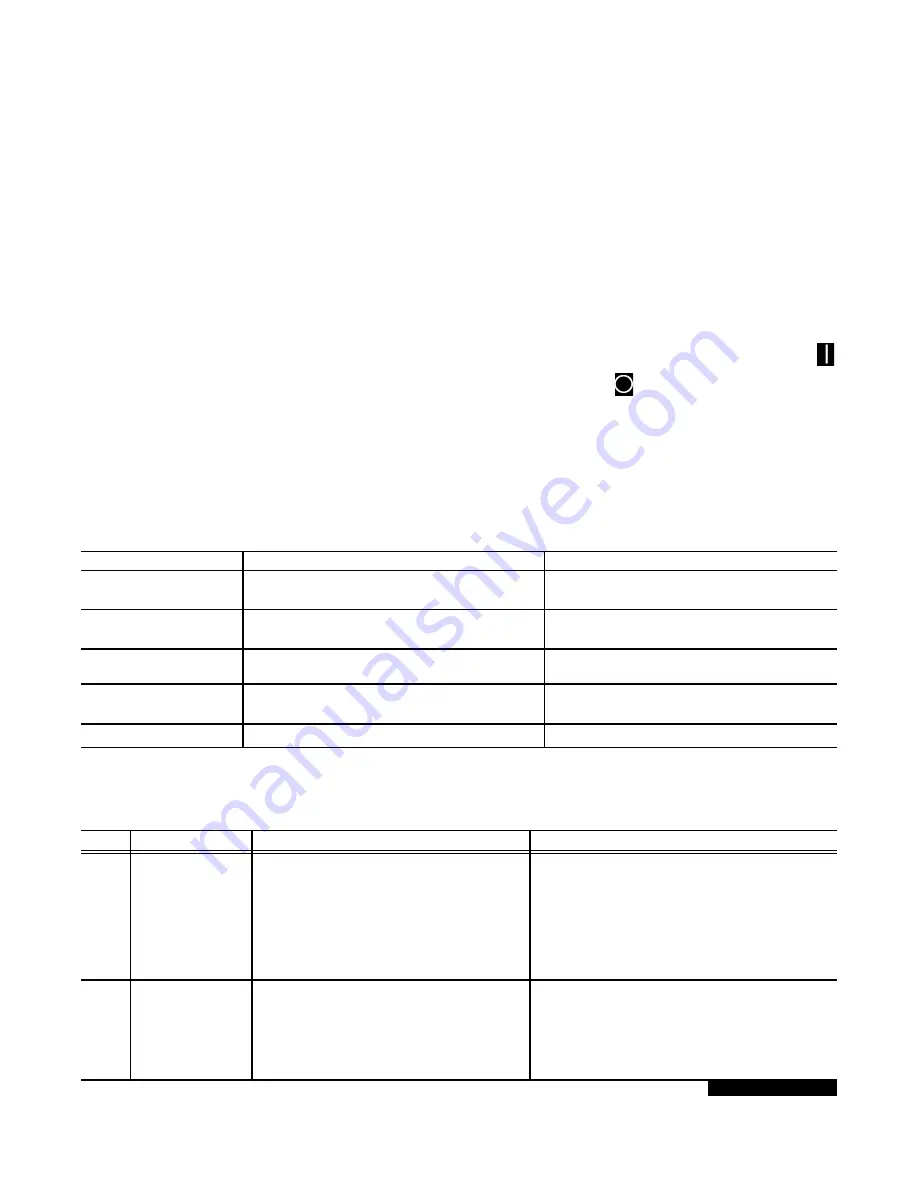

6.6 FAULT AND WARNING CODES

The Supervisor constantly monitors drive performance through the serial channel. The following messages

are specifically displayed by the Supervisor in the event of problems.

FAULT

VSD Param Lim Fault

VSD Com Error

VSD Emergency Stop

(VSD Code 51)

VSD Com Fault

(VSD code 53)

Drive Fault xx

POSSIBLE CAUSE

Incorrect model, HP or Voltage selected in

Factory & VSD Setup

Communications lost with the VSD

Emergency Stop is pressed

Break in Estop wiring

Communications problems detected reported

by the VSD

Problem reported by the VSD

SOLUTION

Make proper selections.

Check connections to the VSD. Check VSD

control power and check for board faults.

Clear the package emergency stop.

Check Estop wiring to the drive input.

Check connections to the VSD. Check VSD

control power and check for board faults.

Refer to fault codes in table below.

Drive fault codes are used for least-likely faults. The Supervisor will display these as "Drive Fault" with a code

number. If a keypad service tool is plugged into the drive, it will display the fault code and the fault name

shown in the first two columns.

1

2

Overcurrent

Overvoltage

The variable speed drive has detected a

high current (>4xIn) in its output due to:

• sudden heavy load increase

• short in the motor

• short in the cables to the motor

• unsuitable motor

The DC-link voltage has exceeded its high

limit due to:

• too short a deceleration time

• high voltage levels or surges in the utility

supply

Check loading.

Check motor.

Check cables.

Make the deceleration time longer.

Use a chopper and brake resistor.

Correct utility supply voltage (level is too high).

Add input impedance to limit surges.

CODE FAULT

POSSIBLE CAUSE

SOLUTION

Continued...

Summary of Contents for SUPERVISOR CONTROLLER Series

Page 6: ...Section 1 SAFETY 2 Figure 1 1A Decals...

Page 8: ...4 Section 2 SUPERVISOR DESCRIPTION Figure 2 1 Supervisor Control Panel...

Page 16: ...12 NOTES...

Page 24: ...20 NOTES...

Page 26: ...22 Section 5 WIRING SCHEMATIC DIAGRAMS 5 2 WIRING DIAGRAM SUPERVISOR CONTROL 02250132 198R00...

Page 33: ...29 NOTES...