Section 5

SUPERVISOR

II

18

MOTOR

--- If flashing, indicates the motor overload

contact has opened.

INLET FILTER

--- If flashing, indicates that inlet filter

maintenance is needed.

OIL FILTER

--- If flashing, indicates that oil filter

maintenance is needed (oil filter differential pres-

sure dP2 maximum has been reached).

POWER ON

--- Lit if 120VAC power is applied to the

Supervisor II.

ON

--- If lit steady, the compressor is running. If

flashing, indicates that the compressor is armed

but stopped because of restart timer not expired,

remote stop or sequence stop.

The compressor

may start at any time.

AUTO

--- If lit steady, the compressor is running and

in auto mode. If flashing, indicates that the com-

pressor is armed but stopped because of restart

timer not expired, remote stop or sequence stop.

The compressor may start at any time.

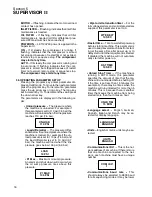

5.5 OPERATING PARAMETER SETUP

Pressing the program key enters parameter dis-

play and edit mode. To move to the next parameter

press the program key. To increment a parameter

press the up arrow key or logo key. The logo key

will increment by 10. To decrement the value press

the down arrow key.

The parameters are displayed in the following or-

der:

S

Unload pressure

--- The pressure where

the machine is unloaded. For example if

this parameter is set to 110 psi (7.6 bar) the

machine will unload when the line pressure

reaches 110 psi (7.6 bar).

UNLOAD

110 PSI

S

Load differential

--- The pressure differ-

ential below the unload pressure where the

machine is loaded. For example if the un-

load pressure is set to 110 psi (7.6 bar) and

the load differential is set to 10 psid (0.7

bar), the machine will load when the line

pressure goes below 100 psi (6.9 bar).

LOAD

10 PSI

S

P1 Max

--- Maximum oil sump pressure.

An alarm and shut down will occur when

the oil sump pressure rises above this

pressure.

P1 MAX

135 PSI

S

Wye to delta transition timer

--- For the

full voltage starters and solid state starters

supplied, this parameter is set to 0.

WYE DELT

10 SEC

S

Restart time

--- Time to wait after powerup

before starting machine. This parameter is

used to keep several machines from start-

ing at the same time after power up, or to

delay start until other equipment is started.

If disabled the machine will not automati-

cally start after power up.

RST TIME

10 SEC

S

Unload Stop Timer

--- If the machine is

running in AUTO mode, this parameter

specifies the amount of time that the ma-

chine will run unloaded before shutting off.

If the time is set less than 15 minutes (for

example 5), there may be times when the

machine will run unloaded for more than 5

minutes. This is because there is another

timer that keeps the machine from being

started more than four times an hour.

UNLD TIM

15 MIN

S

Language select

--- English, German,

Spanish, Italian and French may be se-

lected for display language.

LANGUAGE

ENGLISH

S

Units

--- English or metric units may be se-

lected.

UNITS

ENGLISH

S

Communications ID #

--- This is the net-

work address of a machine. If there is more

that one machine connected to the net-

work, each machine must have a unique

number

COM ID #

1

S

Communications baud rate

--- This

should always be selected to 9600 baud

for all sequencing modes. It may be lower

Summary of Contents for DR-13 Series

Page 6: ...NOTES ...

Page 14: ...8 NOTES ...

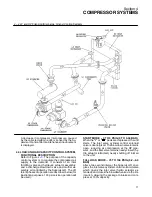

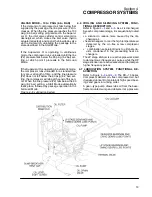

Page 18: ...Section 4 COMPRESSOR SYSTEMS 12 Figure 4 5 Piping and Instrumentation Diagram Air cooled ...

Page 21: ...Section 5 SUPERVISOR II 15 Figure 5 1 Supervisor II Panel ...

Page 28: ...22 NOTES ...

Page 32: ...26 NOTES ...

Page 42: ...Section 7 MAINTENANCE 36 Table 1 Installation Data ...

Page 46: ...40 NOTES ...

Page 48: ...Section 9 ILLUSTRATIONS AND PARTS LIST 42 9 3 COMPRESSOR MOTOR AND FRAME ...

Page 50: ...Section 9 ILLUSTRATIONS AND PARTS LIST 44 9 4 AIR INLET SYSTEM ...

Page 52: ...Section 9 ILLUSTRATIONS AND PARTS LIST 46 9 5 COOLER ASSEMBLY ...

Page 54: ...Section 9 ILLUSTRATIONS AND PARTS LIST 48 9 6 LP HOT LP COLD ...

Page 56: ...Section 9 ILLUSTRATIONS AND PARTS LIST 50 9 7 HP DISCHARGE ...

Page 58: ...Section 9 ILLUSTRATIONS AND PARTS LIST 52 9 8 LUBE SYSTEM ...

Page 60: ...Section 9 ILLUSTRATIONS AND PARTS LIST 54 9 9 ELECTRICAL BOX ...

Page 62: ...Section 9 ILLUSTRATIONS AND PARTS LIST 56 9 10 CONTROL SYSTEM CONDENSATE DRAIN ...

Page 64: ...Section 9 ILLUSTRATIONS AND PARTS LIST 58 9 11 CANOPY ...

Page 66: ...Section 9 ILLUSTRATIONS AND PARTS LIST 60 9 12 DECALS ...

Page 68: ...Section 9 ILLUSTRATIONS AND PARTS LIST 62 9 12 DECALS ...

Page 70: ...Section 9 ILLUSTRATIONS AND PARTS LIST 64 9 12 DECALS ...

Page 72: ...Section 9 ILLUSTRATIONS AND PARTS LIST 66 9 13 DECAL LOCATIONS ...

Page 74: ...Section 9 ILLUSTRATIONS AND PARTS LIST 68 9 13 DECAL LOCATIONS ...

Page 76: ...Section 9 ILLUSTRATIONS AND PARTS LIST 70 9 13 DECAL LOCATIONS ...

Page 78: ...Section 9 ILLUSTRATIONS AND PARTS LIST 72 9 14 WIRING DIAGRAM ...

Page 79: ...NOTES ...