SECTION 2

300HH, 375, 375H, 375HH, 425 AND 425H USER MANUAL R00

19

The control system can easily be adjusted for

pressures from 80 to 125 psig (5.6 to 8.6 bar) for

standard machines, from 80 to 150 psig (5.6 to 10.3

bar) for “H” machines and from 80 psig to 200 psig

(5.6 to 13.8 bar) for “HH” machines. The compressor

unit is driven by an industrial diesel engine designed

to provide enough horsepower to provide an

adequate reserve under rated conditions.

Refer to the

Engine Operator’s Manual

for a more

detailed description of the engine. The engine

cooling system is comprised of a radiator, charge air

cooler, high capacity fan, and thermostat. The high

capacity fan pushes air through the radiator to

maintain the engine’s specified operating

temperature. The same fan also cools the fluid in the

compressor cooling and lubrication system.

The engine radiator, charge air cooler, and the

compressor fluid cooler are next to each other

allowing the fan air to push through all three

simultaneously. As air passes through the fluid

cooler, the heat of compression is removed from the

fluid. The compressor’s high capacity fuel tank

contains enough fuel for one eight hour shift under

normal operating conditions.

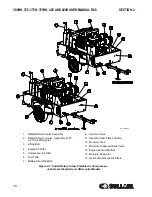

2.3

SULLAIR COMPRESSOR

UNIT, FUNCTIONAL

DESCRIPTION

Sullair compressors are single-stage, positive

displacement, flood lubricated-type compressors that

provide continuous (pulse-free) compression to meet

various demand loads. Sullair compressors require

no routine maintenance or inspection of their internal

parts or systems. The compressor works by injecting

fluid into the compressor unit where it mixes directly

with the air as the rotors turn: the rotor’s rotation

compresses the air. The fluid flow has three main

functions:

1. It acts as a coolant, to control the rise of air

temperature which is generated by compres-

sion (heat of compression).

2. Seals the leakage paths between the rotors

and the stator and also between the rotors

themselves.

3. Lubricates the rotors allowing one rotor to

directly drive the other.

After the air fluid mixture is discharged from the

compressor unit, the fluid is separated from the air.

At this time, the air flows to the service line and the

fluid is cooled in preparation for re-injection.

2.4

COMPRESSOR COOLING

AND LUBRICATION

SYSTEM, FUNCTIONAL

DESCRIPTION

. The compressor cooling and

lubrication system is designed to provide adequate

lubrication as well as maintain the proper operating

temperature of the compressor. In addition to the

fluid cooler and interconnecting piping, the system

consists also of three other components: a fluid filter,

thermal valve, and a fan which perform the following

functions:

• The fluid filter removes and collects any contami-

nants in the fluid.

• The thermal valve functions as a temperature regu-

lator directing fluid either to the cooler or to the

compressor unit.

• The fan pushes air through the cooler dissipating

the heat resulting from compression of the fluid.

The functions of the lubrication system are explained

in more detail below. Fluid is used in the system as a

coolant and as a lubricant: the sump serves as the

fluid reservoir. At start-up, fluid flows from the sump

to the fluid thermal valve. Fluid circulation is achieved

by forcing the fluid from the high pressure region of

the sump to a lower pressure area in the compressor

unit. A minimum pressure device (See

Discharge System, Functional Description

20) is provided to assure adequate fluid flow under

all conditions. When entering the thermal valve upon

start-up, the fluid temperature is cool and thus it is

not necessary to route it through the cooler. The fluid

flows through the fluid filter and on to the compressor

unit bypassing the cooler. As the compressor

continues to operate, the temperature of the fluid

rises and the thermostatic control opens, allowing a

portion of the fluid into the cooler.

When the temperature reaches 155°F (68°C), the

thermostat is fully open allowing all fluid entering the

thermal valve to flow to the cooler.

The cooler is a radiator type that works in concert

with the engine fan. The fan pushes air through the

cooler removing the heat from the fluid. From the

cooler, the fluid is then routed back through the fluid

filter. All fluid flowing to the compressor unit passes

through this filter. The fluid leaving the filter flows to

the compressor unit where it lubricates, seals and

cools the compression chamber; and lubricates the

bearings and gears.

Summary of Contents for 300HH

Page 17: ...SECTION 1 15 Safety Symbols 2 ...

Page 18: ...SECTION 1 16 Safety Symbols 3 ...

Page 49: ...SECTION 2 300HH 375 375H 375HH 425 AND 425H USER MANUAL R00 47 2 9 WIRING DIAGRAM ...

Page 60: ...NOTES 58 ...

Page 79: ...NOTES ...