300HH, 375, 375H, 375HH, 425 AND 425H USER MANUAL R00

SECTION 2

20

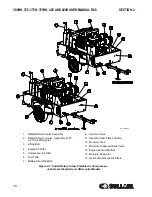

1. Fluid Cooler

2. Engine

3. Compressor

4. Thermal Valve

5. Fluid Filter

6. Receiver Tank

Figure 2-2: Compressor Cooling and

Lubrication System

2.5

COMPRESSOR DISCHARGE

SYSTEM, FUNCTIONAL

DESCRIPTION

. The Sullair compressor unit

discharges a compressed air/fluid mixture into the

receiver tank. The receiver tank has three functions:

1. It acts as a primary fluid separator.

2. Serves as the compressor fluid reservoir.

3. Houses the air/fluid separator.

The compressed air/fluid mixture enters the receiver

tank and is directed against the side of the sump.

Because of a change of direction and reduction of

velocity, large droplets of fluid separate and fall to the

bottom of the sump. The small amount of fluid

remaining in the compressed air collects on the

surface of the separator element as the compressed

air flows through the separator. As more fluid collects

on the element surface, it then flows to the bottom of

the separator. A return line (or scavenge tube) leads

from the bottom of the separator element to the inlet

region of the compressor unit. Fluid collecting on the

bottom of the separator element is returned to the

compressor by the pressure difference between the

area surrounding the separator element and the

compressor inlet. An orifice (protected by a strainer)

is included in this return line to assure proper and

unobstructed flow. The receiver tank is code rated at

250 psig (17.1 bar) working pressure. A minimum

pressure device located downstream from the

separator, ensures a minimum receiver pressure of

80 psig (5.5 bar) during all conditions. Keeping this

pressure level stable is necessary for proper air/fluid

separation and proper fluid circulation. A pressure

relief valve (located on the wet side of the separator)

is set to open if the sump pressure exceeds 250 psig

(17.1 bar).

Fluid is added to the receiver tank through a capped

fluid filler.

2.6

CAPACITY CONTROL

SYSTEM, FUNCTIONAL

DESCRIPTION

Refer to

. The

purpose of the control system is to regulate the

amount of air intake and match it to the demand

(required output) on the compressor. The control

system consists of a pressure regulating valve(s), air

inlet valve, system blowdown valve, pressure

transducer, speed control module, and tubing

connecting the various components of the

compressor and engine. The functional descriptions

of the control system are described by relating them

to four distinct phases of operation. They apply to

any control system with the exception of those with

specified pressures which are dependent on

pressure requirements. The given values apply to a

compressor with an operating pressure range of 100

to 110 psig (6.9 to 7.6 bar).

S

TART

—0 T

O

40

PSIG

(0 T

O

2.8 B

AR

)

When the compressor is started, the sump pressure

quickly rises from 0 to 40 psig (0 to 2.8 bar). During

this period the pressure regulator valve is inactive. At

this pressure range the idle warm-up control keeps

3

2

1

4

5

6

SU_0000664

WARNING

DO NOT remove caps, plugs and/or other

components when the ocmpressor is run-

ning or pressurized. Stop the compressor

and relieve all internal pressure before

removing these items.

Summary of Contents for 300HH

Page 17: ...SECTION 1 15 Safety Symbols 2 ...

Page 18: ...SECTION 1 16 Safety Symbols 3 ...

Page 49: ...SECTION 2 300HH 375 375H 375HH 425 AND 425H USER MANUAL R00 47 2 9 WIRING DIAGRAM ...

Page 60: ...NOTES 58 ...

Page 79: ...NOTES ...