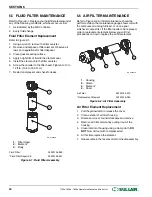

6.7 SEPARATOR MAINTENANCE

Replace the separator element when indicated by the WS

Controller or after one (1) year, whichever comes first. The

separator element must be replaced. DO NOT attempt to

clean the separator element.

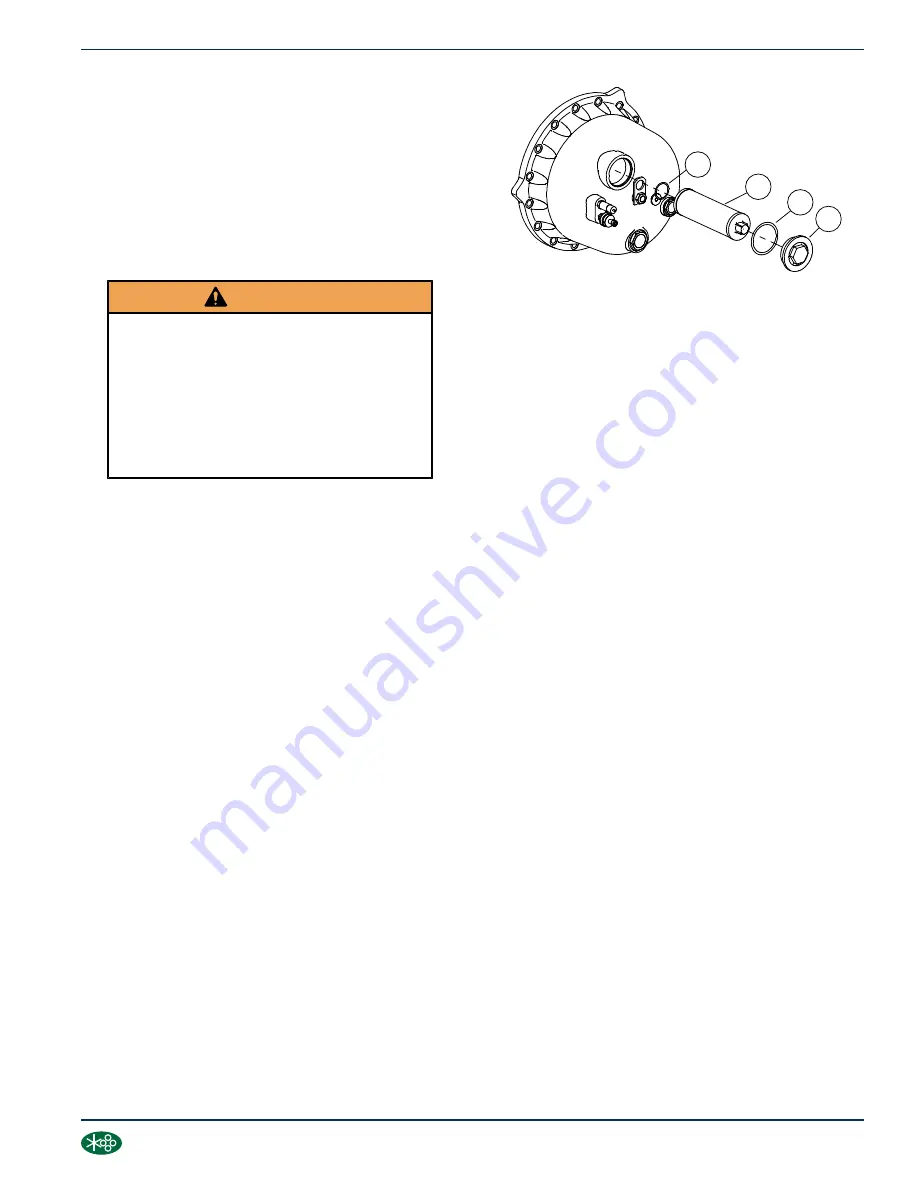

Separator Element Replacement

Refer to Figure 6-3. The separator should be changed

once a year. Follow the procedure explained below for

element replacement:

WARNING

Before performing compressor

maintenance, disconnect the

compressor from the power source

and lock out the power source. Isolate

the compressor from the line

pressure by closing the

recommended discharge shut-off

valve and releasing all internal

pressure from the compressor.

1. Insert a 100mm maximum length, 6mm diameter pin

into the radial-drilled hole in the separator cap. Loosen

and rotate counterclockwise to remove the cap.

2. Pull out the old element by gripping the end of the

element with channel lock pliers or a similar tool.

3. Remove the separator element.

4. Once the separator is removed, the separator fluid

return line can be accessed for removal and cleaning.

5. Install the new O-rings on the separator cap and

separator element filter. Oil lightly to make installation

easier.

6. Insert and push the new element into place.

7. Reinstall the cap. Hand-tighten using a 100mm

maximum length, 6mm diameter pin in the radial-

drilled hole.

SU_0000093

1

2

3

4

1. O-ring*

2. Separator Element

3. O-ring*

4. Cap

Separator Element:

02250160-776

*Separator Replacement Kit:

02250160-774

Figure 6-3: Separator Element Assembly

MAINTENANCE

®

SULLAIR

®

1100e, 1500e, 1800e Operator’s Manual and Parts List

41

Summary of Contents for 1107e

Page 101: ...THIS PAGE INTENTIONALLY LEFT BLANK...